How to Install Wilwood Black Superlite 4R Big Brake Front Kit on your Wrangler

Shop Parts in this Guide

- Wilwood Superlite 4R Front Big Brake Kit; Black Calipers (07-18 Jeep Wrangler JK)

- Wilwood Superlite 4R Front Big Brake Kit; Red Calipers (07-18 Jeep Wrangler JK)

- Wilwood Superlite 4R Front Big Brake Kit with Drilled Rotors; Black Calipers (07-18 Jeep Wrangler JK)

- Wilwood Superlite 4R Front Big Brake Kit with Drilled Rotors; Red Calipers (07-18 Jeep Wrangler JK)

Warning

IT IS THE RESPONSIBILITY OF THE PERSON INSTALLING ANY BRAKE COMPONENT OR KIT TO DETERMINE THE SUITABILITY OF THE COMPONENT OR KIT FOR THAT PARTICULAR APPLICATION. IF YOU ARE NOT SURE HOW TO SAFELY USE THIS BRAKE COMPONENT OR KIT, YOU SHOULD NOT INSTALL OR USE IT. DO NOT ASSUME ANYTHING. IMPROPERLY INSTALLED OR MAINTAINED BRAKES ARE DANGEROUS. IF YOU ARE NOT SURE, GET HELP OR RETURN THE PRODUCT. YOU MAY OBTAIN ADDITIONAL INFORMATION AND TECHNICAL SUPPORT BY CALLING WILWOOD AT (805) 388-1188, OR VISIT OUR WEB SITE AT WWW.WILWOOD.COM. USE OF WILWOOD TECHNICAL SUPPORT DOES NOT GUARANTEE PROPER INSTALLATION. YOU, OR THE PERSON WHO DOES THE INSTALLATION MUST KNOW HOW TO PROPERLY USE THIS PRODUCT. IT IS NOT POSSIBLE OVER THE PHONE TO UNDERSTAND OR FORESEE ALL THE ISSUES THAT MIGHT ARISE IN YOUR INSTALLATION. RACING EQUIPMENT AND BRAKES MUST BE MAINTAINED AND SHOULD BE CHECKED REGULARLY FOR FATIGUE, DAMAGE, AND WEAR.

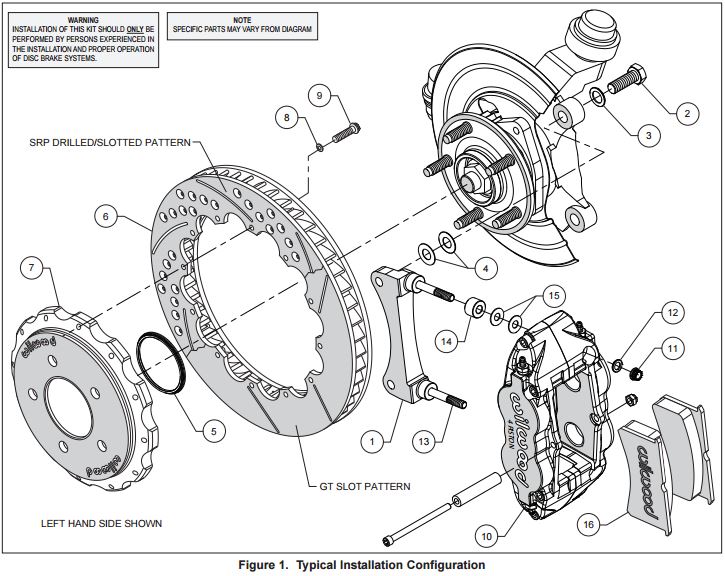

Exploded Assembly Diagram

General Information & Disassembly Instruction

•Installation of this kit should ONLY be performed by persons experienced in the installation and proper operation of disc brake systems. Before assembling this Wilwood front disc brake kit, double check the following to ensure a trouble free installation.

• Inspect the contents of this kit against the parts list to ensure that all components and hardware are included.

• Make sure this is the correct kit to fit the exact make and model year of your vehicle. This kit is designed for direct bolt-on installation to 2007 through present model year Jeep JK Series axle hubs.

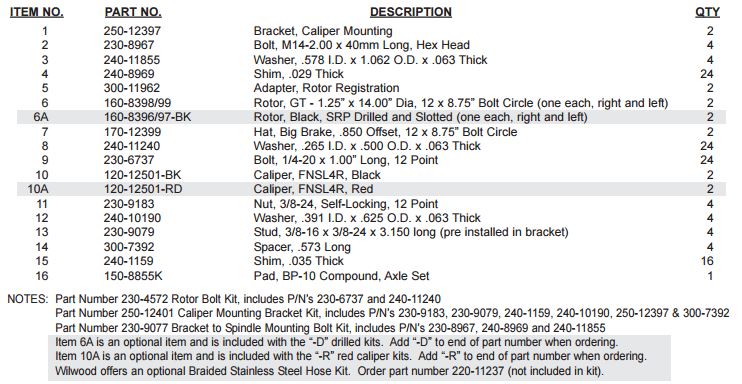

• Verify your wheel clearance using Figure 2.

• Verify that the factory axle hub center register diameter and lug pattern match those in the new adapter ring and hat. NOTE: Axle hubs that have been modified with different size studs or lug patterns may require modifications to the new hat that must be performed by a qualified machinist.

Disassembly

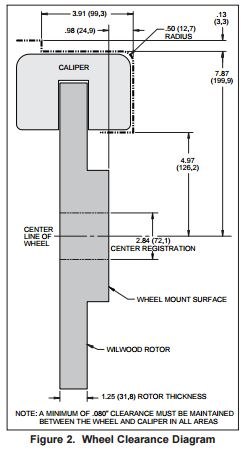

• Disassemble the original equipment front brakes: Raise the front wheels off the ground and support the front suspension according to the vehicle manufacturer’s instructions. Remove the front wheels, calipers and rotors.

• Remove any nicks or burrs on the axle hub and upright that may interfere with the installation of the new brake components.

• Clean and de-grease the axle hub, dust shield, and caliper mounting bosses.

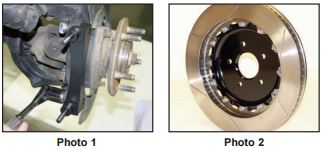

Assembly Instructions (numbers in parenthesis refer to the parts list and Figure 1 on the preceding pages):

• The caliper mount bracket (1) should initially be installed with clean, dry threads on the mounting bolts. Orient the bracket as shown in Figure 1 and Photo 1 and install using mount bolts (2) and washers (3). Initially place two .029” thick shims (4) on each bolt between the bracket and upright, Figure 1. Temporarily tighten the mounting bolts. NOTE: The bracket must fit squarely against the mount bosses on the upright. Inspect for interference from casting irregularities, machining ridges, burrs, etc. Later, after the caliper alignment has been checked, the mount bolts will be secured using red Loctite® 271.

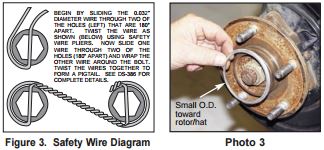

• Orient the rotor (6) and the hat (7) as shown in Figure 1 and Photo 2. Attach rotor to hat using bolts (9) and washers (8). Using an alternating sequence, apply red Loctite® 271 to the threads, and torque to 155 in-lbs. For an added measure of security, the bolts may be safety wired using standard 0.032 inch diameter stainless steel safety wire as shown in Figure 3.

Please refer to Wilwood’s data sheet DS-386 (available at www.wilwood.com/Pdf/DataSheets/ds386.pdf) for complete safety wire installation instructions.

• Slide the rotor registration adapter (5) onto the axle register on the axle hub with the smaller O.D. facing outward, Photo 3.

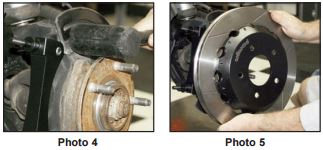

• The dust shield may need to be slightly bent inward for the new hat/rotor assembly to fit properly, Photo 4. Test fit hat/rotor and bend the dust shield as necessary to allow a minimum of .12” clearance..

• Slide the hat/rotor assembly onto the axle hub, Photo 5.

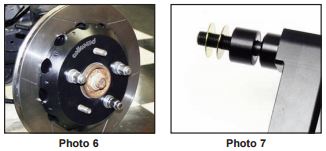

NOTE: The hat must fit flush against the axle hub flange or excessive rotor run out may result. Install three lug nuts (finger tight) to keep the hat/rotor assembly in place while continuing with the installation, Photo 6.

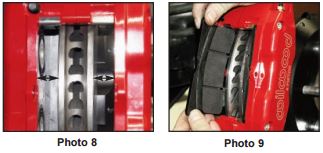

• Lubricate the caliper mounting studs (13) with lightweight oil. Initially place two .035” thick shims (15) and one spacer (14) on each stud as shown in Figure 1 and Photo 7. Mount the caliper (10) onto the bracket (1) using lock nuts (11) and washers (12), Figure 1. Temporarily tighten the lock nuts and view the rotor through the top opening of the caliper. The rotor should be centered in the caliper, Photo 8.

If not, adjust by adding or subtracting shims (4) between the bracket and the upright. Always use the same amount of shims on each of the two mounting bolts. Once the caliper alignment is correct, remove the bracket mounting bolts one at a time, apply red Loctite® 271 to the threads, and torque to 75 ft-lb.

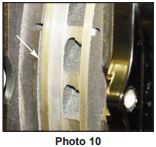

•Remove the caliper center bridge pad retainer bolt, nut, and tube from the caliper. Insert the brake pads (16) into the caliper, with the friction material facing the rotor, as shown in Photo 9. Check that the top of the brake pad is flush with the outside diameter of the rotor, Photo 10. If not, adjust by adding or subtracting shims (15) between the caliper and the bracket. After the caliper pad height is set, torque the caliper lock nuts (11) to 30 ft-lb. Secure the brake pads in place with the center bridge pad retainer tube, bolt, and locknut. The locknut should be snug without play in the bolt or tube. Be cautious not to over tighten.

• Temporarily install the wheel and torque the lug nuts to the manufacturer’s specification. Ensure that the wheel rotates freely without any interference.

•NOTE: OEM rubber brake hoses generally cannot be adapted to Wilwood calipers. The caliper inlet fitting is a 1/8-27 NPT. The preferred method is to use steel adapter fittings at the caliper, either straight, 45 or 90 degree and enough steel braided line to allow for full suspension travel and turning radius, lock to lock. Wilwood offers a brake flex line hose kit to fit this application, order P/N 220-11237. Hose kit includes hoses, fittings, etc., all in one package for this application. Carefully route hoses to prevent contact with moving suspension, brake or wheel components.

NOTE: Wilwood hose kits are designed for use in many different vehicle applications and it is the installer's responsibility to properly route and ensure adequate clearance and retention for brake hose components.

•NOTE: Specified brake hose kits may not work with all Years, Makes and Models of vehicle that this brake kit is applicable to, due to possible OEM manufacturing changes during a production vehicle's life. It is the installer's responsibility to ensure that all fittings and hoses are the correct size and length, to ensure proper sealing and that they will not be subject to crimping, strain and abrasion from vibration or interference with suspension components, brake rotor or wheel.

•In absence of specific instructions for brake line routing, the installer must use his best professional judgment on correct routing and retention of lines to ensure safe operation. Test vehicle brake system per the 'minimum test' procedure stated within this document before driving. After road testing, inspect for leaks and interference. Initially after install and testing, perform frequent checks of the vehicle brake system and lines before driving, to confirm that there is no undue wear or interference not apparent from the initial test. Afterwards, perform periodic inspections for function, leaks and wear in a interval relative to the usage of vehicle.

• Bleed the brake system, referring to the additional information and recommendations on page 6 for proper bleeding instructions. Check system for leaks after bleeding.

•Install the wheel and torque the lug nuts to manufacturer’s specifications.

•Fill and bleed the new system with Wilwood Hi-Temp° 570 grade fluid or higher. For severe braking or sustained high heat operation, use Wilwood EXP 600 Plus Racing Brake Fluid. Used fluid must be completely flushed from the system to prevent contamination.

NOTE: Silicone DOT 5 brake fluid is NOT recommended for racing or performance driving.

•To properly bleed the brake system, begin with the caliper farthest from the master cylinder. Bleed the outboard bleed screw first, then the inboard. Repeat the procedure until all calipers in the system are bled, ending with the caliper closest to the master cylinder. NOTE: When using a new master cylinder, it is important to bench bleed the master cylinder first.

•Test the brake pedal. It should be firm, not spongy and stop at least 1 inch from the floor under heavy load. If the brake pedal is spongy, bleed the system again. If the brake pedal is initially firm, but then sinks to the floor, check the system for fluid leaks. Correct the leaks (if applicable) and then bleed the system again. If the brake pedal goes to the floor and continued bleeding of the system does not correct the problem, a master cylinder with increased capacity (larger bore diameter) may be required. Wilwood offers various lightweight master cylinders with large fluid displacement capacities.

•NOTE: With the installation of after market disc brakes, the wheel track may change depending on the application. Check your wheel offset before final assembly.

•If after following the instructions, you still have difficulty in assembling or bleeding your Wilwood disc brakes, consult your local chassis builder, or retailer where the kit was purchased for further assistance.

Bedding Steps for New Pads & Rotors - All Compounds

Once the brake system has been tested and determined safe to operate the vehicle, follow these steps for the bedding of all new pad materials and rotors. These procedures should only be performed on a race track, or other safe location where you can safely and legally obtains speeds up to 65 MPH, while also being able to rapidly decelerate.

• Begin with a series of light decelerations to gradually build some heat in the brakes. Use an on-and-off the pedal technique by applying the brakes for 3-5 seconds, and then allow them to fully release for a period roughly twice as long as the deceleration cycle. If you use a 5 count during the deceleration interval, use a 10 count during the release to allow the heat to sink into the pads and rotors.

• After several cycles of light stops to begin warming the brakes, proceed with a series of medium to firm deceleration stops to continue raising the temperature level in the brakes.

• Finish the bedding cycle with a series of 8-10 hard decelerations from 55-65 MPH down to 25 MPH while allowing a proportionate release and heat-sinking interval between each stop. The pads should now be providing positive and consistent response.

• If any amount of brake fade is observed during the bed-in cycle, immediately begin the cool down cycle.

• Drive at a moderate cruising speed, with the least amount of brake contact possible, until most of the heat has dissipated from the brakes. Avoid sitting stopped with the brake pedal depressed to hold the car in place during this time. Park the vehicle and allow the brakes to cool to ambient air temperature.

COMPETITION VEHICLES

• If your race car is equipped with brake cooling ducts, blocking them will allow the pads and rotors to warm up quicker and speed up the bedding process.

• Temperature indicating paint on the rotor and pad edges can provide valuable data regarding observed temperatures during the bedding process and subsequent on-track sessions. This information can be highly beneficial when evaluating pad compounds and cooling efficiencies.

POST-BEDDING INSPECTION – ALL VEHICLES

• After the bedding cycle, the rotors should exhibit a uniformly burnished finish across the entire contact face. Any surface irregularities that appear as smearing or splotching on the rotor faces can be an indication that the brakes were brought up to temperature too quickly during the bedding cycle. If the smear doesn’t blend away after the next run-in cycle, or if chatter under braking results, sanding or resurfacing the rotors will be required to restore a uniform surface for pad contact.

PRE-RACE WARM UP

• Always make every effort to get heat into the brakes prior to each event. Use an on-and-off the pedal practice to warm the brakes during the trip to the staging zone, during parade laps before the flag drops, and every other opportunity in an effort to build heat in the pads and rotors. This will help to ensure best consistency, performance, and durability from your brakes.

DYNO BEDDED COMPETITION PADS AND ROTORS

• Getting track time for a proper pad and rotor bedding session can be difficult. Wilwood offers factory dyno-bedded pads and rotors on many of our popular competition pads and Spec 37 GT series rotors. Dyno-bedded parts are ready to race on their first warm up cycle. This can save valuable time and effort when on-track time is either too valuable or not available at all, Dyno-bedding assures that your pads and rotors have been properly run-in and are ready to go. Contact your dealer or the factory for more information on Wilwood Dyno-Bedding services.