Top Sellers for Tundra

How to Install TeraFlex 3" Lift Kit w/o Shocks on your 1997-2006 Wrangler

Tools Required

- Torx bits (T50 & T55)

- Pitman arm puller

- Electric hand drill

- 5/16" and 13/32" drill bits

- Jack stands and a jack

- Other standard hand tools

- 3/8 NC Hand Tap (2003 +)

Shop Parts in this Guide

Rear Installation (first)

1. Jack up the rear of the TJ by the frame and secure with jack stands.

2. Remove the rear tires and rear shocks.

3. Remove the rear sway bar links.

4. Remove rear springs.

5. Remove the rear rubber bump stops by grasping the bump stop and pulling down with a side to side motion. (Located at the top of each coil spring.)

6. Use a 15mm socket to remove the bolt inside both bump stop cups.

7. Install rear bumpstop extensions. 3” kit installers: With a 16mm socket and new bolt (10mm x 55mm 1.5 pitch) remove the bump stop cup, and place the spacer (1.5” OD x 1.5” tall) between the bump stop cup and the bump stop pedestal. 4” & 5” kit installers: follow the above directions using new bolt (10mm x 75mm 1.5 pitch) and spacer (2” OD x 2.25” tall).

8. Remove the plastic dust shield that covers the bolt securing the rear track bar to the rear axle housing. You will no longer need this shield.

9. Remove the size T55, Torx headed bolt and set it aside. (Note: It is easy to remove and replace the front and rear track bars with the TJ on the ground.) Tie the track bar end up out of the way while you install the track bar extension bracket.

10. Hold the rear track bar bracket extension over the axle bracket positioned as show in Figure 1. Using one of the bolts (1/2” x 3” nc) and the spacer (1.5” x 1”OD x .5”ID) insert them in the hole vacated by the Torx headed bolt. Use the spacer to fill the spot the track bar once occupied. This will keep the bracket from

.png)

collapsing when the new bolt is tightened.

11. With the track bar bracket in place, the two (2) smaller holes in the bracket should line up close to the holes in the axle bracket vacated by the plastic shield removed in Step 8.

12. Using a 5/16” drill bit, drill out the small holes upper and lower to make room for installing the (5/16” x 1”) bolts and nuts and washers. Install and tighten the bolts and nuts.

13. Line up the track bar with the upper holes in the new track bar bracket and use the Torx bolt and nut you removed in Step 9 to secure the bar in place.

14. Install the new TeraFlex rear springs (6.50” OD).

15. Install the replacement shocks. When using the Doetsch Tech MV series shocks, mount the shock with the canister up for improved clearance on the axle housing. Do not mount other brands upside down.

16. Install the new longer sway bar links using two rubber bushings on each end of the link. Reuse the bolts you took out of the stock links to install the new longer ones. Push the plastic sleeve over the shank of each bolt. Insert the bolt with sleeve into the bushings in the link ends. Use one of the (1/2” SAE) flat washers between the sway bar and the rubber bushing. This will cause the bushing to compress more. Using the nut you removed, tighten the sway bar links into place.

Front Installation (second)

Rear Installation Complete.

1. Jack up the front of the TJ by the frame and set stands in place.

2. Remove the front tires and front shocks. Remember to save those lower bolts.

3. Disconnect the lower end of the front sway bar link to allow the front axle to drop.

4. Remove the spring clamp and bolt and set aside.

5. Remove the front springs. Passenger side first.

6. Remove the bump stop cushions and the bolts in the bump stop cup.

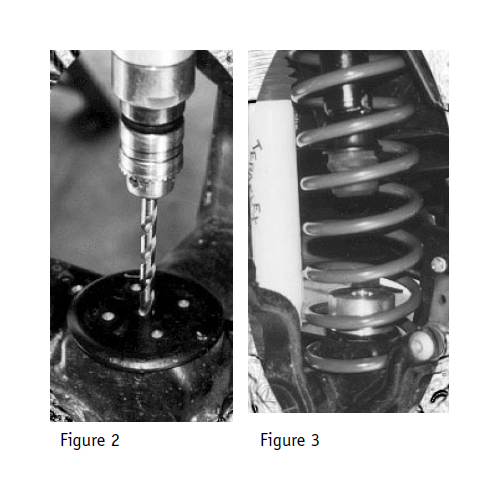

7. Using an electric hand drill and a 5/16” drill bit, locate the center of the front, lower spring pad. The divot in the center works well as a guide. Drill a hole through the guide in the pad as shown in Figure 2.

8. Using the aluminum spacer as a guide, screw one of the self-tapping bolts (3/8” x 2”) into each hole to cut the threads and then remove the bolt and set aside.

Note: 2003 and newer TJ’s have a thick plate here. You will need to drill and tap this with a thread tap. The self tapping bolts won’t cut threads in the heavy plate.

9. Install the front TeraFlex springs. Right side first.

Set the aluminum spacer (3”OD) inside the TeraFlex spring as you put it up into place. Once the spring is in place, rotate the spring so the bottom end of the spring butts up against the stop in the axle pad support.

10. Replace the spring clamp and bolt taken out in Step 4.

11. Replace the upper bump stop cup, bolt and cushion removed in Step 6.

12. Install the front shocks. Put the tires and wheels back on.

13. Remove the stock pitman arm from the drag link and the steering gear. You will most likely need a pitman arm puller. We recommend renting a good one from a tool rental place rather than buying a cheap one.

14. Install the new TeraFlex drop pitman arm.

NOTE: The 3T DOES NOT include the drop pitman arm.

Do NOT connect the drag link yet.

15. Straightening the steering wheel Our goal is to find the neutral location for the front axle. If we do this, the steering wheel will be very close to center. Make sure the Jeep is on flat, level ground. Remove the passenger side (right side) of the front track bar. With the Jeep on the ground and the steering wheel locked in its center position bounce the Jeep up and down. Use the front bumper to do this. After you have done this the front suspensions and steering should be in a neutral position. Without moving any other components raise the lower end of the track bar up into its mounting bracket. Using the track bar center hole as a guide mark the bracket. If you have room in the bracket so the hole does not overlap the edges go ahead and drill the hole out. Make sure you are drilling at a right angle to the bracket when drilling through to the rear half of the bracket. Use a 13/32” drill bit. If you drilled the hole in the correct location you should be able to just lift the bar up and insert the

.png)

Drill the front track bar bracket to remount the track bar in the position that will center the axle underneath the vehicle.

new 10mm x 75 mm bolt.

If there is not enough room to re-drill the track bar mount then an adjustable front track bar must be purchased. An adjustable track bar will allow you to fine tune the correct length needed to center the axle underneath the vehicle.

You should now connect the drag link to the drop pitman arm.

Fine tuning the steering:

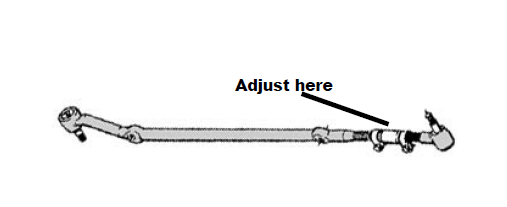

Adjust the sleeve on the front drag link by loosening the clamps and twisting the sleeve in a direction that causes drag link to become shorter. Find a place you can drive that is flat and straight. Adjust the sleeve and test drive the TJ until your steering wheel is centered to your satisfaction and tighten the adjuster sleeve clamps.

Note: If your Jeep is not level when you put it back on the ground, loosen all bolts and retighten with the Jeep on the ground.

Transfer Case Lowering Kit Installation

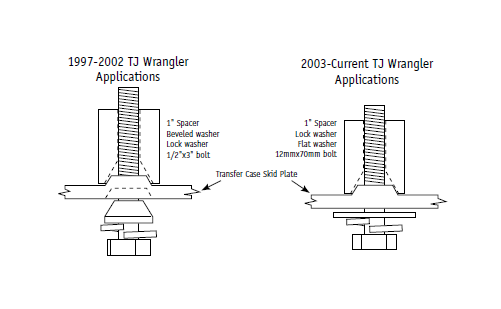

1. 1997-2002 TJ Wranglers- Install the six spacers (1.25”OD x 1.25” tall) between the frame and the cross member with the flat end of the spacer up against the frame. The 1/2” lock washer goes onto the 1/2” x 3” bolt first followed by the tapered washer with the flat end of the tapered washer against the lockwasher.

2. Put the tires and wheels back on if needed and lower the TJ to the ground.

1. 2003-current TJ Wranglers- Install the six spacers (1.25”OD x 1.25” tall) between the frame and the cross member with the flat end of the spacer up against the frame. The 1/2” lock washer goes onto the M12 x 1.75 x 70 bolt first followed by the 1/2” flat washer.

2. Put the tires and wheels back on if needed and lower the TJ to the ground.

Troubleshooting

Driveline vibration

This section applies if the stock driveshaft is used. If a CV style driveshaft is installed this section will not apply.

Acceleration vibration - The vibration is caused by the pinion angle being to high in relation to the transfer case output shaft.

Deceleration vibration - This vibration is caused by the pinion angle being too low in relation to the transfer case output shaft.

If you have constant vibration when accelerating or decelerating, see which of these actions causes the vibration to decrease in severity. If you accelerate and the vibration diminishes you need to bring the yoke up.

Because the axle is mounted in rubber, the axle will rotate in the rubber under torque. TeraFlex has lower and upper control arms available which are adjustable. With the FlexArms from TeraFlex, you can adjust your pinion angles to eliminate vibration.

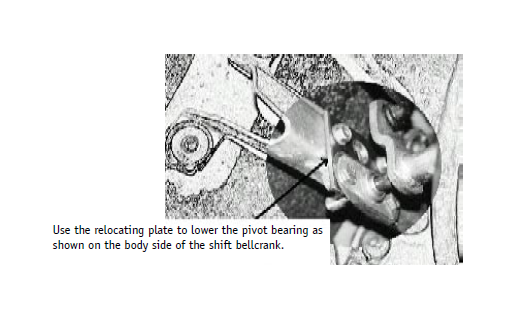

Relocator Plate

Note: 99 percent of the lifts don’t require the relocator plate. You do not need to install this plate if-

1. You are not using the transfer case lowering kit.

2. Your transfer case shifts fine into 4 Low.

The relocator plate is no longer included in the kit. Please call us if you are having problems shifting into 4 Low.

If you have any questions or problems with this suspension kit, contact your local dealer or contact us at Tera Manufacturing.

Alignment notes

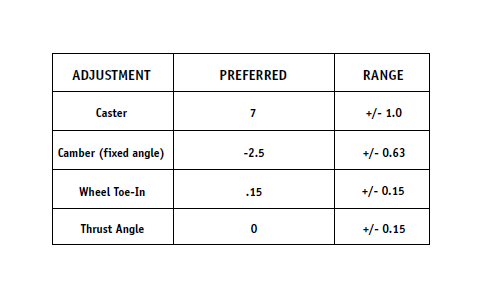

After installation of the TeraFlex suspension kit, it is imperative that the front end alignment angles be checked. It is recommended that your TJ be taken to a reputable alignment shop that understands 4WD vehicles and has experience with their alignment parameters.

There are three basic alignment angles: camber, caster, and toe-in. Camber is pre-set by the manufacturer and cannot be adjusted. If the camber angle is off, this could indicate that something is bent.

Caster might be changed with the installation of our suspension kit. It is recommended that the factory specifications be maintained. If this cannot be obtained with the caster adjustment eccentrics found on the lower control arms, you may opt for our FlexArms (flexible lower control arms) which allow for additional adjustment.

Toe-in is also important for tire wear. Toe-in may be affected on a three-inch kit, and will be affected on a four-inch kit. It has been recommended that the toe-in be set to minimum factory specifications if you go to the larger tire and wheel set up.

Optional Accessories Available-

Suspension System Kit (part #ST)

includes front/rear lower flexarms, steering box skidplate, and sway bar disconnects.

TeraFlex FlexArms

front/rear lower flexarms (part #FATJ)

front upper control arms (part# FAFU)

rear upper control arms (part# FARU)

Steering Box Skidplate (part #SBSPT)

Sway Bar Disconnects (part #QDFT)