Top Sellers for Grand Cherokee

How to Install Rough Country Front Dana 44 CV Driveshaft for 3.5-6 in. Lift (07-11 Jeep Wrangler JK) on your Jeep Wrangler

Installation Time

2 hours

Tools Required

- Jack Stands

- Floor Jack

- Red Threadlock

- RTV (Black/Red/Gold)

- 13mm wrench

- 8 mm Socket

- 15 mm Socket

- 5/16 Socket

- 32 mm Socket

- 1 1/8 Socket

- Long ratchet or breaker bar

- Torque Wrench

- Hammer

- Awl

- Large Flathead Screwdriver

Rough Country Front Dana 44 CV Driveshaft for 3.5-6 in. Lift (07-11 Jeep Wrangler JK)

Model Number J125828

This guide is for installing the Rough Country Front Dana 44 CV Driveshaft for 3.5-6 in. Lift (07-11 Jeep Wrangler JK). Read all instructions carefully before starting.

Before

After

Installation Instructions:

1. Park vehicle on level ground, and apply the parking brake (or place vehicle in park), place wheel chocks in front of and behind the rear wheels.

2. Safely raise the front tires off of the ground and support the vehicle with jack stands rated for the weight of the vehicle. Refer to vehicle manual for proper jack stand locations.

3. Inspect new driveshaft and parts. You should have the front and rear yoke, u-join straps, and the driveshaft.

4. Unbolt the 8 bolts at the rear of the driveshaft at the transfer case using an 8 mm socket. This hardware will not be reused. If necessary, you can put the jeep in 4wd to keep the driveshaft from spinning. If you leave at least one bolt partially in, it will make removal of the front bolts easier.

5. Using a 15 mm socket, unbolt the front of the driveshaft at the front differential flange. Retain these bolts as they will be reused with the new driveshaft.

6. At the rear end of the driveshaft, you will find small indentations for an awl at the end of the yoke (see pictures). Gently tap the awl into these indentations evenly to separate the driveshaft from the CV yoke.

7. Remove the driveshaft from the vehicle and set it aside. Be careful, it is heavy.

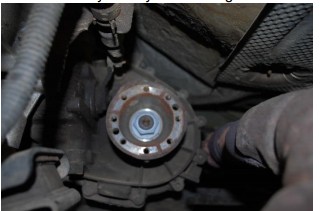

8. Place the vehicle in 4wd and, using a 32 mm socket, remove transfer case yoke nut. This may require some force so you may need a long ratchet or breaker bar.

9. Using a puller, remove yoke. If you do not have a puller, you may be able to tap the yoke off with a small hammer, but be careful you do not damage the transfer case.

10. Remove the o-ring from the factory yoke and install it in the same position in the new transfer case yoke.

11. Gently place new yoke in place where old one was, making sure the splines line up easily. Put RTV on the yoke nut along with a drop or two of red threadlocker and reinstall. Tighten to 160 ft-lbs.

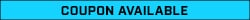

12. Move to the front differential. Using a 1 1/8 socket and your long ratchet or breaker bar, remove the front axle pinion nut. A small amount of gear oil may drip, this is not abnormal.

13. Using a puller, remove the front pinion yoke.

14. Place the new pinion yoke on splines and push it as far onto the pinion as you can by hand.

15. Put RTV on the front pinion nut (like you did on the rear one) along with a couple of drops of red threadlocker and reinstall the nut. The pinion nut is used to set preload on the crush collar in the differential and must not be overtightened – torque to 160 ft-lbs.

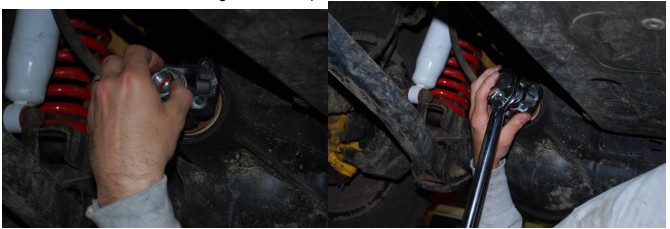

16. Install new driveshaft. Tighten U-joint straps on transfer case end with 5/16 socket. Use red thread locker on each of the bolts; tighten to 15 ft-lbs. It is really tight and you may not have a torque wrench.

Note: that will fit in here – do not overtighten as the u-joint caps can be crushed.

17. Align the front of the driveshaft with the new pinion flange. Install the included u-joint straps to hold the driveshaft to the pinion flange using a 13mm wrench. Use a drop of blue threadlocker on each bolt and tighten to 15 ft-lbs. The likelihood of getting any kind of torque wrench in there is slim – use a short ratchet and do not over-tighten.

18. Once all bolts have been tightened fully, driveshaft installation is complete. Grease the driveshaft before lowering the vehicle to the ground.

Installation Instructions Written by ExtremeTerrain Customer Michael E. 6/26/2019