How to Install Rough Country 2.5" Series II Lift Kit on your 2007-2013 Wrangler

Tools Required

- 10mm Wrench

- 14mm Socket

- 16mm Wrench

- 16mm Socket

- 18mm Wrench

- 18mm Socket

- 19mm Deep Well Socket

- Jack

- Jack Stands

Shop Parts in this Guide

Rough Country recommends a certified technician install this system. In addition to these instructions, professional knowledge of disassemble/reassembly procedures as well as post installation checks must be known. Attempts to install this system without this knowledge and expertise may jeopardize the integrity and/or operating safety of the vehicle.

Please read instructions before beginning installation. Check the kit hardware against the kit content list on this page and the kit layout on the back page. Be sure you have all needed parts and know where they go. Also please review tools needed list and make sure you have needed tools. As a general rule, the taller a vehicle is, the easier it will roll. Seat belts and shoulder harnesses should be worn at all times. Avoid situations where a side rollover may occur.

Rough Country makes no claims regarding lifting devices and excludes any and all implied claims. We will not be responsible for any product that is altered.

This system was developed to provide a level stance to the Jeep after it is lifted. You will note that the front lift is 2.5” and the rear lift is 2”. This is intentional and is the look most often requested. Also you will note that this lift does not modify the front or rear track bar or its mounting points. This will result in what is generally considered an insignificant shift in both the front and rear axle of approx 1/4 of an inch. Rough Country offers an optional rear track bar bracket to address this. Please call your nearest Rough Country dealer to inquire.

This suspension system was developed using a 285/75R17” tire with factory wheels. If bigger/wider tire are used with the factory wheels or factory offset wheels you must carefully check the clearance during turning between the tires and the lower control arm and the front sway bar link before driving. If you have any questions concerning the design, function, and correct use of our products contact us at 800-222-7023.

IMPORTANT NOTES : The draglink must be adjusted to the center steering wheel BEFORE the vehicle is driven. Failure to do so will cause a computer error in the Jeep’s traction control system.

On Automatic equipped vehicles; due to use of an oversize driveshaft from the factory and inadequate factory clearance it may be possible for the front driveshaft to come in to contact with the automatic transmission pan tearing the factory boot and rubbing on the shaft. Generally this occurs during heavy articulation when front sway bar links are disconnected and longer shocks are installed. If this is found to occur, the proper procedure would be to replace the oversize factory shaft with an aftermarket smaller diameter shaft to increase

clearance between the transmission and front driveshaft. Rough Country does offer this driveshaft if needed.

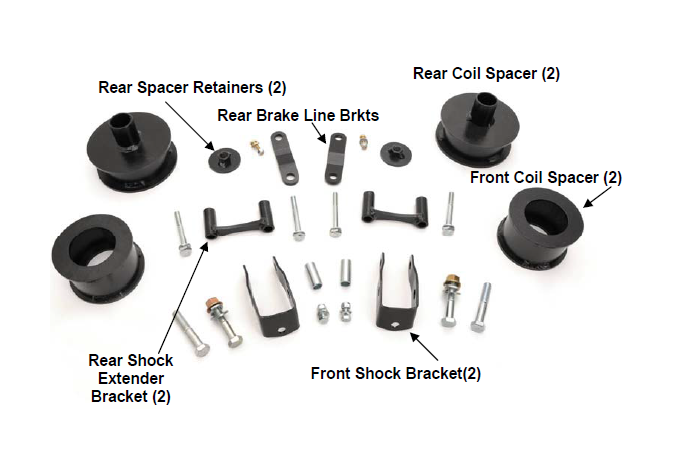

Kit Contents:

2— Front Coil Spring Spacers

2— Rear Coil Spring Spacers

2— Front Shock Extension

2— Rear Shock Extension

2—Rr Brake Line Ext Brkts

1--Poly Bag Containing:

2-.1/2” X 2 3/4” Bolts

2-1/2” lock washers

4-10mm x 80mm Bolts

4-10mm flat washers

2-Rear spacer retainers

2-12mm nuts

2-12mm x 65mm bolt

2-washers

2-5/16 x 3/4” bolt

2-5/16” nuts

4-5/16” washers

2-1/4” x 1” Bolts

2-1/4” Lock Nuts

4-1/4” Flat washers

FRONT INSTALLATION INSTRUCTIONS

1. Chock the rear wheels and jack up the front of the vehicle and support the vehicle with jack stands so that the front wheels are off the ground.

2. Using a 19mm deep well socket remove the front tires/wheels,

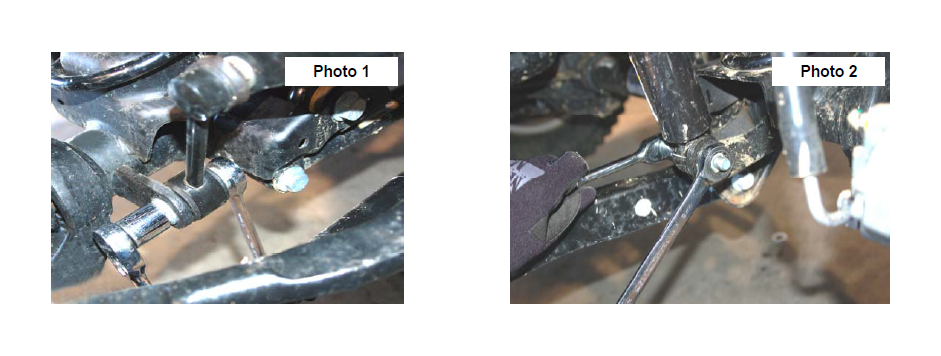

3. Using a 18mm socket and wrench remove the bottom sway bar bolts. Retain hardware for later use. See Photo 1

4. Using a 18mm socket and wrench remove the lower shock bolt. See Photo 2. Retain the lower hardware for reuse.

5. Using a 10MM socket, remove the brake line bracket from the stock location.

6. Push down on the axle to allow room for the coils to be removed. Remove coil springs, and factory spring isolator.

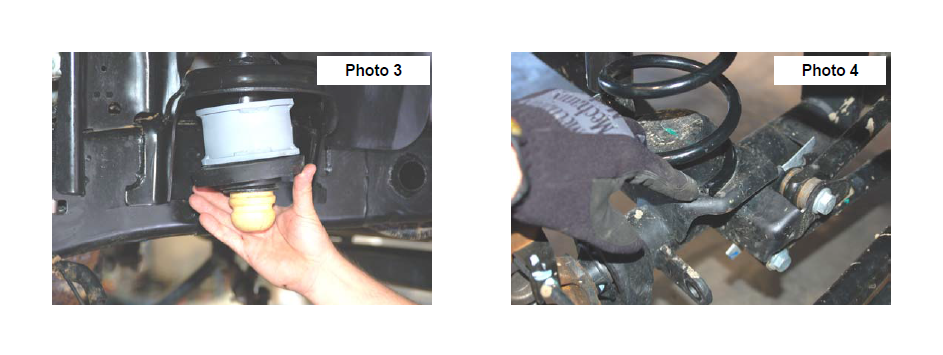

7. Install the new spacer over the factory bump stop with the factory isolator as shown See Photo 3.

8. Reinstall the factory coil spring. Be sure to rotate the spring until the pigtail hits the stop. See Photo 4.

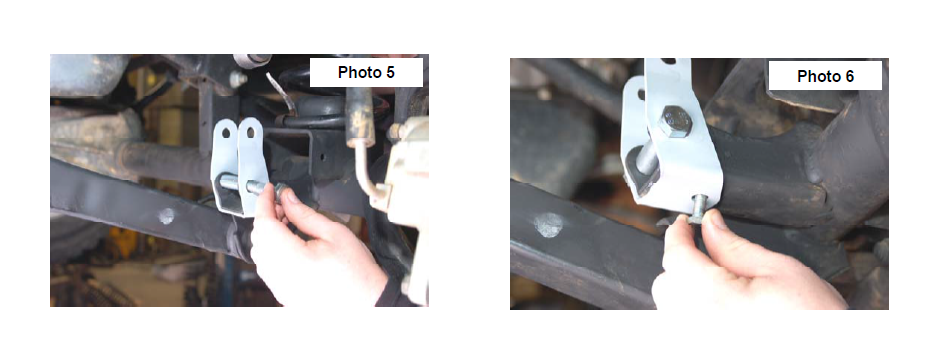

10. Install the shock bracket as shown in Photo 5 on the lower front mount at this time with supplied 12mm sleeves, 12mm x 65mm bolts and 5/16” x 3/4” bolts. See Photo 6. Tighten using a 18mm for the12mm bolt and a 1/2” for the 5/16”.Please note that there is a right and left side and the bracket will only install one way.

11. Install the stock shock with the factory bolt in the lower shock mount and tighten using a 18mm socket and wrench.

12. Reinstall the front tires/wheels and tighten to factory specifications.

13. Remove the jack stands and lower the vehicle to the ground. Install the sway bar links on the sway bar using factory hardware using a 18mm wrench after the vehicle is on the ground. Do not install the sway bar link on the sway bar until the sway bar is on the ground.

14. The draglink must be adjusted to center the steering wheel BEFORE the vehicle is driven. Failure to do so will cause a computer error with the Jeep’s traction control system and will result in odd handling and poor performance.

REAR INSTALLATION INSTRUCTIONS

1. Chock front wheels and jack up the rear of the vehicle and support the vehicle with jack stands so that the rear wheels are off the ground. Remove the rear tires/wheels, using a 19mm deep well socket.

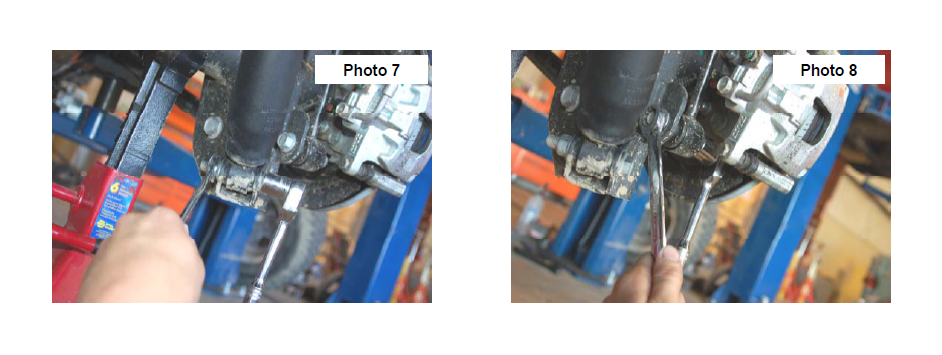

2. Remove the upper shock bolt using a 16mm socket and wrench. Remove the lower shock bolt using a 18mm socket and wrench and remove the factory shock. See Photo 7. Retain the lower shock hardware for reuse.

3. Using a 18mm socket and wrench remove the bottom sway bar bolts. Retain hardware for later use. See Photo 8.

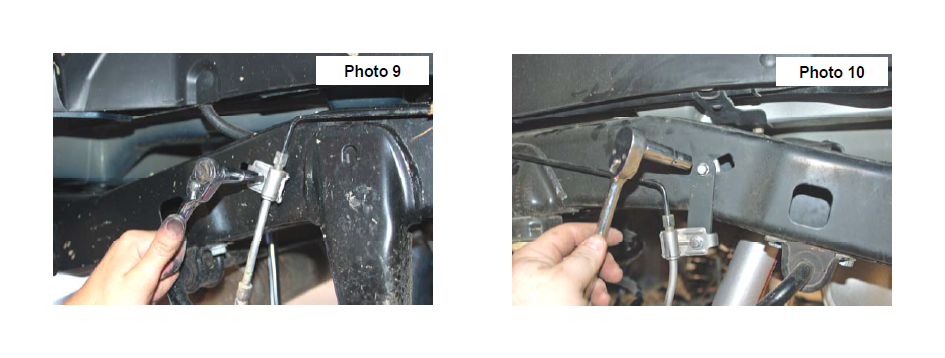

5. Using a 10mm wrench remove the bolt holding the brake line to the frame. See Photo 9.

6. Attach the brake line bracket to the location on the frame where the factory bracket was attached. Tighten using a 10mm wrench and stock hardware. Secure the factory bracket to the bottom hole of the relocation bracket using a 7/16 wrench and the supplied .250-20 x 1” bolts, washers, and nuts. See Photo 10.

7. Push down on the axle to allow enough room for stock coil spring to be removed. Remove the stock coil spring and isolator.

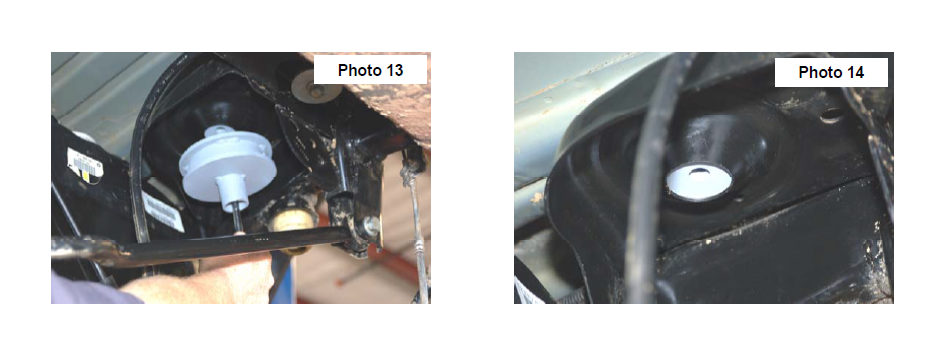

8. Install the new coil spring spacer with supplied washer/nut retainer and secure the assembly with supplied 1/2” x 2 3/4” bolt & lock washers through the factory coil mount as shown in Photo 12,13 & 14.

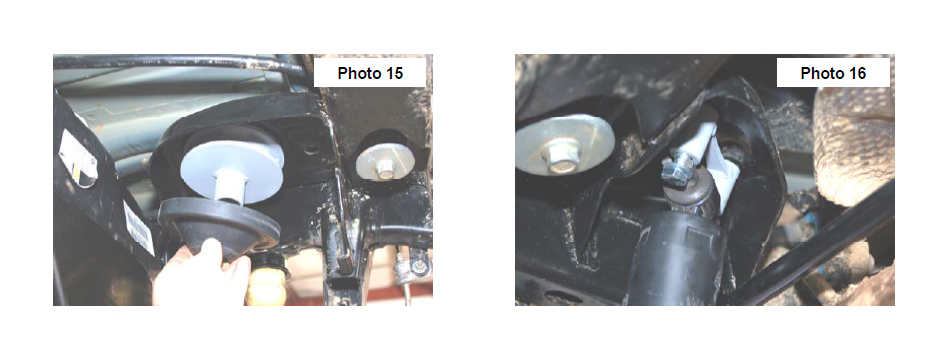

9. Install the factory coil spring isolator as shown. See Photo 15.

10. Install the top of the coil back onto the coil seat. When installing the bottom of the coil into the seat rotate the coil until the pigtail hits the spring stop. Lower vehicle slightly, watching coils to assure they properly seat on top.

11. Reinstall the sway bar link using a 18mm socket and wrench using the stock hardware. Install the brake line bracket removed in step 5 using factory hardware.

12. Install the rear shock extender brackets with the supplied 10mm x 80mm bolts/washers as shown in Photo 16. Reinstall the shock in the lower mount with factory hardware using a 18mm wrench.

13. Reinstall the rear tires/wheels and tighten to factory specifications. Lower the vehicle to the ground.

POST INSTALLATION

1. Check all fasteners for proper torque. Check to ensure there is adequate clearance between all rotating, mobile, fixed and heated members. Check steering for interference and proper working order. Test brake system.

2. Perform steering sweep. Cycle the steering from full turn to full turn to check for clearance. Failure to perform inspections may result in component failure.

3. The draglink must be adjusted to the center steering wheel POST INSTALLATION

1. Check all fasteners for proper torque. Check to ensure there is adequate clearance between all rotating, mobile, fixed and heated members. Check steering for interference and proper working order. Test brake system.

2. Perform steering sweep. Cycle the steering from full turn to full turn to check for clearance. Failure to perform inspections may result in component failure.

3. The draglink must be adjusted to the center steering wheel BEFORE the vehicle is driven. Failure to do so will cause a computer error with the Jeeps traction control system and result in odd handling and poor performance.

4. Using an certified alignment professional with experience in aligning lifted vehicles, get an alignment done to factory specifications.

5. Readjust headlights to proper settings.

MAINTENANCE INFORMATION

It is the ultimate buyers responsibility to have all bolts/nuts checked for tightness after the first 500 miles and then every 1000 miles. Wheel alignment steering system, suspension and driveline systems must be inspected by a qualified professional mechanic at least every 3000 miles.

INSTALLING DEALER - it is your responsibility to install the warning decal and forward these installation instructions on to the vehicle owner for review. These instructions should be kept in the vehicle for its service life.