How to Install Rough Country 1 In. Motor Mount Lift Kit on your 1987-2006 Wrangler

Shop Parts in this Guide

PREINSTALLATION NOTES

This kit will be installed on one side of the vehicle at a time.

A body lift must be installed to allow this kit to be installed.

Check OE motor mount bushings and studs to make sure they are in good operating shape. If needed new motor

mounts must be installed.

Kit Content:

2-Motor Mount Spacer

2-Studs

2-10mm x 60mm bolts

2-10mm washers

INSTALLATION INSTRUCTIONS

1. Place a floor jack under the bell housing with a block of wood to distribute the weight across the housing. Do not lift the engine using the oil pan as a jack point.

2. Slowly raise the jack to slightly take the pressure off of the motor mounts.

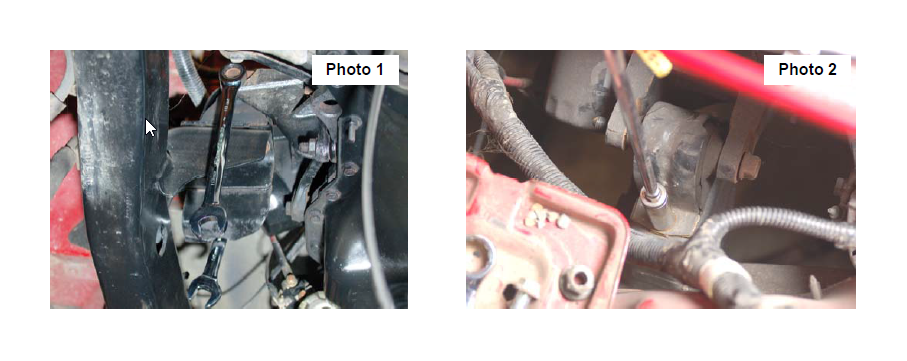

3. Starting on the passenger side of the vehicle, remove the nut from the cross bolt that secures the rubber isolator to the engine support bracket using a 18mm & 19mm wrench. See Photo 1.Do not remove the cross bolt at this time.

4. Remove the stock bolts and nuts that secure the mount to the frame using a 15mm wrench. Retain the factory hardware. See Photo 2.

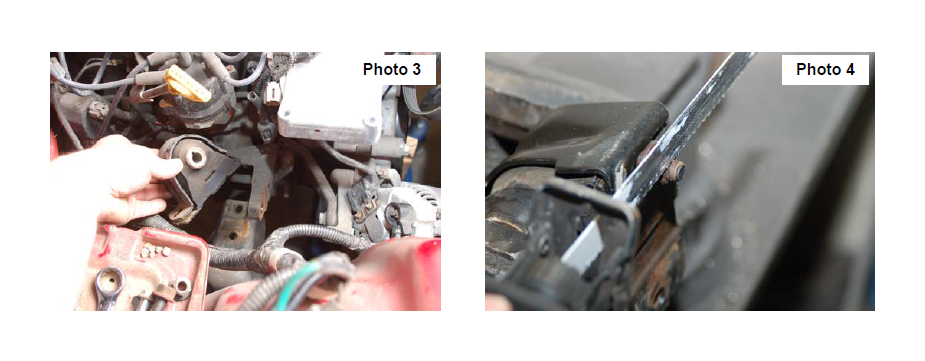

5. Remove the cross bolt and remove the isolator from the vehicle. See Photo 3. NOTE: On vehicles equipped with a 4cyl motor, it will be necessary to remove the alternator to remove the stock cross bolt from the isolator. Also on vehicles equipped with air conditioning, the condenser pump will not allow enough clearance to remove the stock cross bolt, therefore the engine support bracket must be removed.

6. Using a cutting tool, remove 1/4” from the motor mount stud. Take care not to damage the threads. See Photo 4.

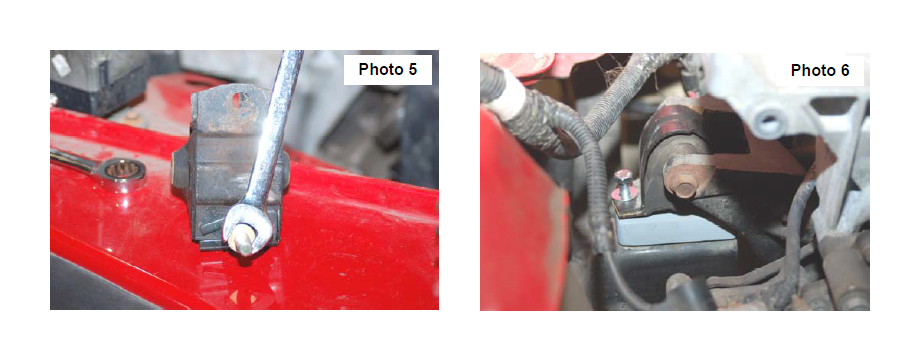

7. Install the supplied stud extension onto the stud and tighten using a 16mm wrench. Make sure the stud extension is fully seated against the bottom of the motor mount. See Photo 5.

8. Slip the motor mount spacer over the stud and reinstall on the vehicle and secure to the frame with the stock nut and the supplied 10mm x 60mm bolt /washer. See Photo 6. Do not fully tighten at this time. If the engine bracket was removed, install it at this time.

9. Adjust the height of the jack and reinstall the stock cross bolt in the mount. Do not tighten.

10. Repeat steps for Driver side. When driver side is completed, tighten all hardware.

POST INSTALLATION

• Check clearance on engine and engine components. Check clearance between the fan and the fan shroud.

• Re torque all fasteners after 500 miles. Visually inspect components and re torque fasteners during routine vehicle service.