How to Install Poison Spyder Trail Corner Guards w/ OEM Tail Light Cutouts - Black on your Wrangler

Tools Required

- Mechanic's tool set (wrenches, screw-drivers, etc. for removal/reinstall of OE equipment)

- C-clamps, bar clamps or vise-grip clamps

- Rags or soft material for use under clamp jaws

- Fine tip felt pen

- Hammer and center punch

- Drill motor and 1 /4" drill bit & 1" hole saw (optional)

- Optional: professional nut-sert installation tool

- Small rat tail file

- Aerosol clear coat or paint

Shop Parts in this Guide

APPLICATIONS

These installation instructions apply to the following Poison Spyder products:

13-06-010-K YJ Trail Corners - OE Taillights - Black SpyderShell

13-06-020-K YJ Trail Corners - LED Taillights - Black SpyderShell

14-06-010-K TJ Trail Corners - OE Taillights - Black SpyderShell

14-06-020-K TJ Trail Corners - LED Taillights - Black SpyderShell (shown)

15-06-010-K U Trail Corners - OE Taillights - Black SpyderShell

15-06-020-K U Trail Corners - LED Taillights - Black SpyderShell

PARTS LIST

Please check your packages immediately upon arrival to ensure that everything listed is included, and to check for damage during shipping. If anything is missing or damaged, call Poison Spyder at (951) 849-5911 as soon as possible.

(1) Driver Side Trail Corner

(1) Passenger Side Trail Corner

Only one of the following Hardware Kits are included:

(1) TJ-YJ Trail Corner Hardware Kit

PN: HWKIT-14-06-010 includes:

(22) 1/4-20X3/4 SS button head socket cap screw

(22) 1/4-20 nylon insert lock nut (22) 1/4 flat washer

(4) 1/4-20 Nut-Sert

(1) 1/4" Nut-Sert Install Tool - includes:

(1) 1/4-20 X 2 Gr8 Hex Head Cap Screw

(2) 1/4" SAE Hardened Flat Washer

(1) 3/8-16 X 1-1/8 Coupling Nut

(1) 1/4-20 Nut-Sert

OR

(1) U Trail Corner Hardware Kit

PN: HWKIT-15-06-010 includes:

(27) 1/4-20X3/4 SS button head socket cap screw

(27) 1/4-20 nylon insert lock nut

(27) 1/4 flat washer

(4) 1/4-20 Nut-Sert

(1) 1/4" Nut-Sert Install Tool - includes:

(1) 1/4-20 X 2 Gr8 Hex Head Cap Screw

(2) 1/4" SAE Hardened Flat Washer

(1) 3/8-16 X 1-1/8 Coupling Nut

(1) 1/4-20 Nut-Sert

INSTALLATION PROCEDURE

1. Park the Jeep on a flat, level surface and engage the emergency brake.

2. Remove taillights, gas filler bezel and any non-original equipment obstructions, saving all mounting hardware for re-use. Be careful when disconnecting the taillight pigtail (do not cut it at this time, disconnect it by carefully disengaging the safety clip on the plug). Remove the plastic inner wheel well by using a pair of dikes to remove the "Christmas tree" plastic fasteners that keep it in place.

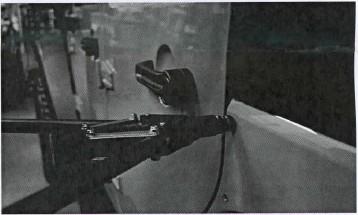

3. Place the Trail Corner against the corner of the Jeep and clamp it into place (use rags or some other soft material between the clamp and the Trail Corner to protect your paint or powder coat finish). Visually check for proper alignment of the Trail Corner and make any adjustments.

Note: At this point there may be a gap between the edge of the Trail Corner and the rear fender flare. This gap is OK at this point, it will be addressed later when the Trail Corners are bolted into place.

4. Use a fine-tip felt pen to mark the mounting hole locations (mark through the mounting holes in the Trail Corner, onto the Jeep's sheet metal). If you purchased Trail Corners for LED taillights, mark the large taillight hole as well.

5. Remove the Trail Corner from the vehicle. Check behind the Jeep's sheet metal at each marked location for wires and other obstructions. Remove, re-locate or hold them out of the way during drilling during the following step.

6. Use a center punch and hammer to lightly mark the center of each of your mounting hole marks. Drill the mounting holes using a 1 /4" drill bit. Use a file to de-burr the edges of the holes.

7. At the driver/passenger bottom rear mounting hole closest to tailgate, an access hole will need to be drilled by drilling all the way through the tub. Then, from inside the tub, use a 1" hole saw centered on the previously drilled through-hole. The resulting 1" hole provides access to the lock nut that will be installed there. Spray exposed bare metal with clear-coat. A CJ7 rubber body plug or generic 1" rubber plug from the hardware store can be used to plug the hole after installation is complete.

OPTIONAL: If desired, rather than cutting the 1" access hole you may install the supplied 1/4" nut-serts in these locations. On Jeep TJ & LJ, it may be easier to use nut-serts at the forward-most hardware locations on either side as well, so we have provided 2 additional nut-serts for this purpose, in the hardware kits for those vehicles. See the procedures in the Appendix for proper use of the supplied Nut-Sert Install Tool.

8. If you are installing LED taillights, use a 4-1 /2" hole saw to cut out the marked hole for the taillight. Use a file to de-burr the edge of the cut.

9. Spray the exposed bare metal around the edges of the holes with aerosol clear coat or other paint of your choice to prevent rust.

10. Place the Trail Corner back onto the vehicle and fasten it into place using the provided hardware. Be sure to place the flat washers on the inside of the Jeep tub, under the lock nuts (NOT under the button heads).

11. If there is a gap between the Trail Corner and the fender flare, loosen the fasteners for the flare and manipulate it into place, snugly against the edge of the Trail Corner (this may require slightly enlarging the mounting holes in the flare).

12. Re-install taillight (unless using LED's) and gas filler bezel, as well as any other components that were removed at the beginning of this procedure.

13. Repeat the previous procedures to install the opposite side Trail Corner.

14. If installing LED taillights, continue with the installation instructions that came with the LED taillights.

APPENDIX: USING THE NUT-SERT TOOL

NOTE: It is HIGHLY RECOMMENDED to invest in a professional nut-sert installation tool, such as the one available from Poison Spyder (p/n: 70-TS-325-RN) or elsewhere. The professional tool will make the installation of nut-serts MUCH easier than using the free tool included in this kit, and it will come in handy with future product installations as well.

The simple "tool" included with this product is admittedly frustrating to use, however it will work for those with patience who would like to save the cost of the professional tool. If using the simple Nut-Sert Installation Tool included with this product, follow this procedure:

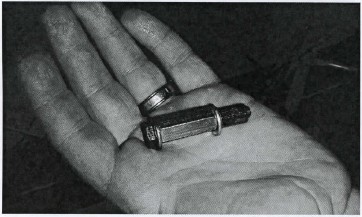

1. The provided nut-sert install tool consists of a bolt, two washers and a coupler (long) nut. Assemble these items as shown (bolt-washer-coupler nut-washer - nut-sert). Insert the nut-sert end of the assembly into the hole you drilled.

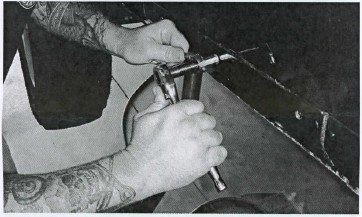

2. Use an open end wrench to hold the coupler nut stationary while turning the head of the bolt clockwise with a ratchet (or small impact wrench) and socket. As you turn the ratchet, the bolt will draw the far end of the nut-sert toward the inside of the sheet metal, gripping it with the knurled outside edge of the nut-sert as it deforms. Continue to turn the ratchet until the nut-sert is fully seated. DO NOT OVER-TIGHTEN as you can damage the nut-sert, or cause it to lose its grip.

3. Once the nut-sert has seated correctly, loosen the bolt then remove it and the rest of the tool from the nut-sert. Install a new nut-sert onto the tool, oriented the same as the last, and set it aside until your next nut-sert installation.

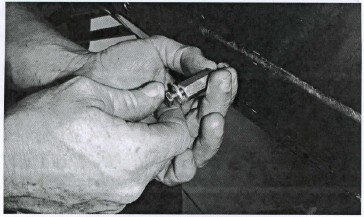

4. With the tool removed, inspect the nut-sert to make sure it is properly seated and that the surrounding sheet metal isn't excessively deformed. Note that some deformation of the sheet metal is normal, and that it will be covered by the part after installation.

If you "spin" a nut-sert: That is, if it loses its grip due to over-tightening or improper installation, the quickest, easiest fix is to use a MIG welder to place a small tack weld at the edge of the nut-sert flange. Before applying the tack weld, sand or grind the paint from a very small area of the sheetmetal where the tack weld will be. Then insert a screw into the nut-sert to protect the threads from weld splatter. Only apply a very small tack or two, as you do not want to heat up and deform the nut-sert or the sheetmetal. Then grind the tack(s) smooth and apply touch-up paint to prevent rust.