Top Sellers for Wrangler

How to Install a Magnaflow Loop Delete Y-Pipe on your 2012-2017 Wrangler JK 2 Door

Shop Parts in this Guide

Warning:

When working on, under, or around any vehicle exercise caution. Please allow the vehicle's exhaust system to cool before removal, as exhaust system temperatures may cause severe burns. If working without a lift, always consult vehicle manual for correct lifting specifications. Always wear safety glasses and ensure a safe work area. Serious injury or death could occur if safety measures are not followed.

** Magnaflow Performance Exhaust recommends professional installation on all their products

Step 1:

(Carefully read all instructions before installation) To detach the OEM Y-Pipe start by removing the skid plate and the bracket under the Y-Pipe, Unbolt the flanges at the converters and loosen the clamp at the rear and remove the Y-Pipe and muffler assembly. retain the clamp as it will be used to re-install the muffler assembly.

Step 2:

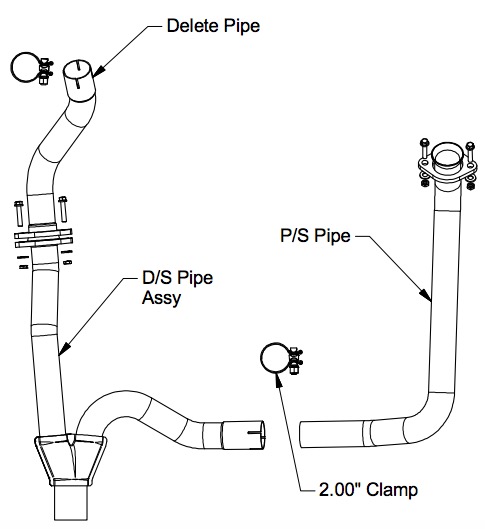

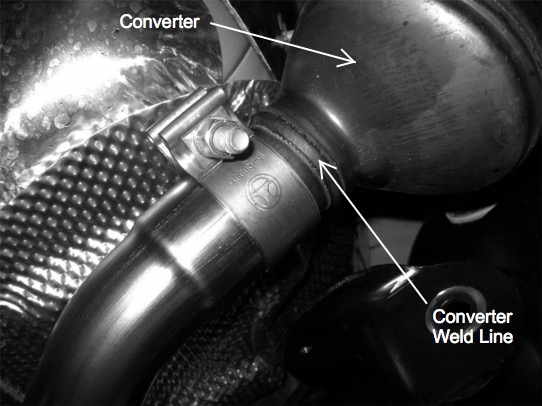

To Prepare the vehicle to accept the Delete Pipe Measure and mark the OEM Circular Pipe 3.00" behind the Converter Weld Line shown in Fig. 1.

Step 3:

With the Pipe still attached at the Flange cut at the measured line. Un-bolt the flange and remove the Circular Pipe from the system.

Step 4:

Slip the inlet end of the new Magnaflow Delete Pipe over the cut converter outlet. Loosely secure using the supplied clamp.

Step 5:

Begin installation of the new Y-Pipe by slipping the right and left sides together (making sure the flange is on the P/S pipe) and loosley attaching using the supplied Band clamp. Keep all clamps and fasteners loose until final assembly. Attach this Y-Pipe Assembly to the vehicle using the supplied fasteners. Re-attach the OEM Pipe and Muffler assemblies as well as the skid plate and bracket removed earlier.

Step 6:

With all components mounted loosely, adjust the system for clearance of frame & bodywork. (MAGNAFLOW recommends at least 1/2" of clearance between the exhaust system and any body panels to prevent heat-related body damage or fire.)

Step 7:

Once a final position has been chosen for the new system, evenly tighten all fasteners from front to rear. The supplied band clamps must be VERY tight to properly align the pipes and prevent leaks (Approximately 40ft-lbs). Inspect all fasteners after 25-50 miles of operation and retighten if necessary.