Top Sellers for Frontier

How to Install a JKS Rear Adjustable Swaybar End Link Kit on your 1997-2006 Jeep Wrangler TJ

Installation Time

30 minutes

Tools Required

- Metric/Standard Socket Wrench Set

- Torque Wrench

- Tape Measure

- 3/4" Open-End Wrench

- Medium Strength Threadlocker

- Wheel Bearing Grease

- Metal Cutting Tool * (such as die grinder with cutting wheel or appropriate saw for cutting connecting rod)

- Factory Service Manual (recommended) *

Shop Parts in this Guide

Welcome

CONGRATULATIONS on your purchase of new JKS Adjustable Swaybar Links! At JKS Manufacturing, we are committed to providing you with the best products available and your satisfaction is our first priority.

PLEASE READ these Installation Instructions carefully, and save them for future reference, as they contain important installation and maintenance information.

Warning

NOT COMPATIBLE WITH aftermarket swaybars. Install product with Original Equipment swaybar only.

Installation

1. REMOVE ORIGINAL EQUIPMENT (OE) REAR SWAYBAR LINKS

Remove the original mounting hardware that secures the rear swaybar links to the swaybar and chassis.

Discard original rear swaybar links, but retain mounting hardware.

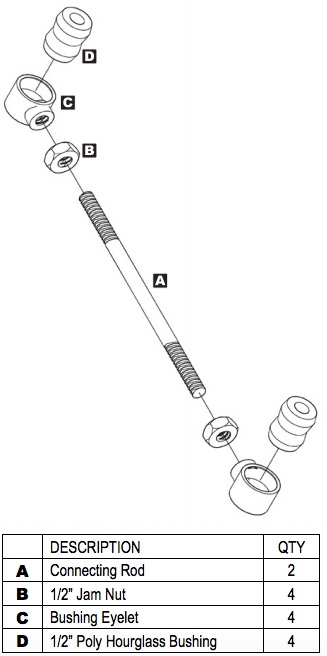

2. DETERMINE PROPER LENGTH OF ADJUSTABLE SWAYBAR LINKS

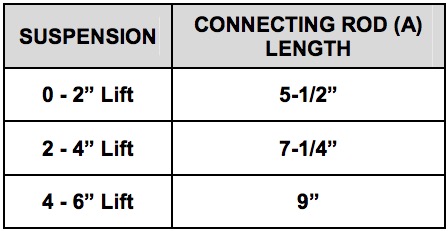

The Adjustable Rear Swaybar Links can be adjusted to any length between 7” and 10-1/2” (measured from center-to-center of bushings). However, the three Recommended Lengths indicated in the chart below will suit most applications.

Choose the Recommended Length from the following chart that corresponds with the amount of rear suspension lift on your vehicle.

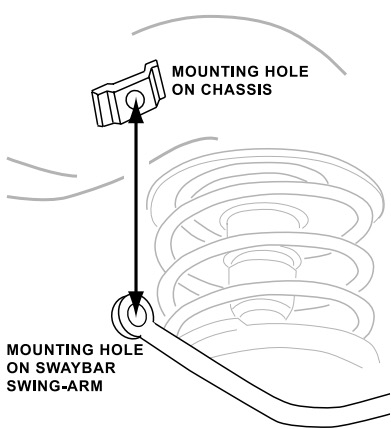

Rotate the rear swaybar until the distance between the original mounting holes on the swaybar and chassis is equal to the Recommended Length* for your vehicle.

Rotate the swaybar up and down to simulate full suspension compression and extension. Check center of swaybar to ensure it does not contact axle housing.

Also check the angle of the swaybar swingarms in relation to the lower rear suspension arms. Optimum performance will be achieved when these components are close to parallel.

If you did not experience the desired results with the Recommended Length, it may be necessary to fine tune the length until desired results are achieved.

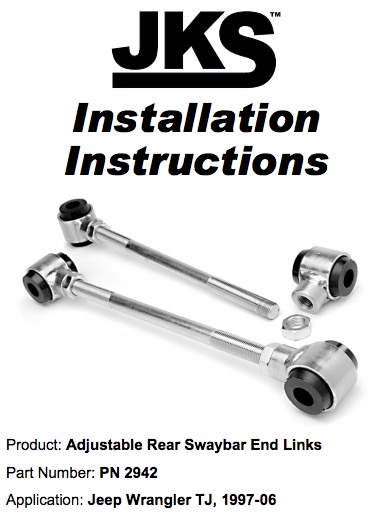

3. MODIFY CONNECTING ROD

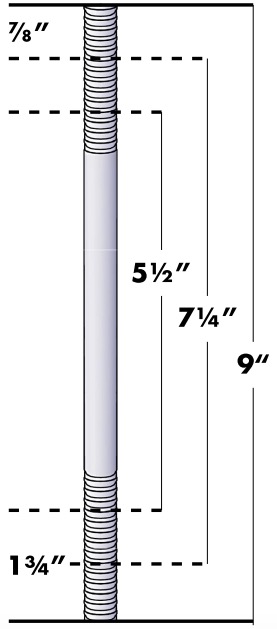

For applications with less than 4” of Suspension Lift, it may be necessary to cut some thread material from each end of the Connecting Rod (A).

HINT: No cutting is required for vehicles with 4-6” of Suspension Lift – proceed directly to Section 4.

Remove Bushing Eyelets (C) from both ends of the Connecting Rod (A).

Refer to the following list to determine the proper Connecting Rod (A) length for your application.

Using the illustration below as a reference, mark each end of the Connecting Rod (A) indicating the appropriate locations to cut.

HINT: Remove same amount of thread material from each end.

3. MODIFY CONNECTING ROD (cont.)

Using an appropriate cutting tool (such as a die grinder with cutting wheel, or metal cutting saw), carefully and squarely cut each end of the Connecting Rod (A) where previously marked.

Now completely unthread both 1/2” Jam Nuts (B) from Connecting Rod (A) and re-install.

HINT: This will help to repair any thread damage that may have occurred during the cutting process.

4. SET FINAL LENGTH OF ADJUSTABLE SWAYBAR LINKS

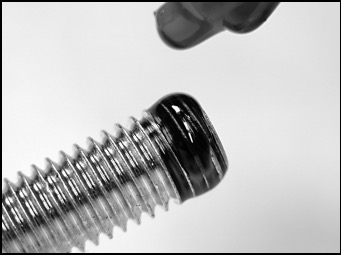

Apply a drop of medium strength thread locking compound to the tip of threads at each end of Connecting Rod (A).

Completely thread a Bushing Eyelet (C) on to each end of Connecting Rod.

5. INSTALL SWAYBAR LINKS

Apply a thin layer of wheel bearing grease to inner surface and sides of Poly Bushings (D).

Using the original mounting hardware, secure the Adjustable Rear Swaybar Links to the swaybar and chassis. Make sure upper and lower Bushing Eyelets (C) are in alignment with their respective mounts.

Once all adjustments are complete, fully tighten the Jam Nuts (B) against the Bushing Eyelets (C) to prevent length of Adjustable Swaybar Links from changing.

Tighten original swaybar link mounting hardware to 40 ft-lbs. using a torque wrench.