How To Install a JKS Front Swaybar Quicker Disconnect System on your 2007-2016 Jeep Wrangler JK

Installation Time

30 minutes

Tools Required

- Metric / Standard Socket Wrench Set

- Torque Wrench

- Medium Strength Threadlocker, (example: Loctite Blue Threadlocker)

- #1 Phillips Screwdriver or Small Punch

- Angle Measuring Tool

- Grease Gun with Zerk Fitting Coupler

- Factory Service Manual (recommended, but optional)

Shop Parts in this Guide

Tools Required:

Metric / Standard Socket Wrench Set:

o 18mm Socket

o 18mm Open Ended Wrench

o 19mm Open Ended Wrench

o 15/16” Open Ended Wrench

Torque wrench

o To apply 65 ft-lbs. of pressure to the new posts that we’ll be installing

Medium Strength Threadlocker, (example: Loctite Blue Threadlocker)

o To apply to the posts before we place the post nut.

o Latex gloves may be useful if you don’t like Loctite on your hands.

#1 Phillips Screwdriver or Small Punch

o Any strong thin shaft will work. This is used to stick inside the post to secure it as you wrench.

Angle Measuring Tool

o This is to make sure your sway bar is in the correct position before you place the new disconnects.

o Your new JKS disconnects are adjustable and if you do not have them set at the correct height, your sway bar will not be at the correct angle.

You may be able to measure your OEM sway bar links to determine the correct angle.

Grease Gun with Zerk Fitting Coupler

o With standard bearing grease

Factory Service Manual (recommended, but optional)

Before you begin

- Be sure you have all of your parts. See the photos below.

- It is recommended to read the safety information in the manual that came with the product. You are using parts which may modify the way your vehicle handles. Never drive without your sway bar connected on public roads and highways.

- This guide is a community guide and is not written or meant to replace the factory guide. Author is not liable for any damages, injuries, or other events or issues that occur.

Step 1: Familiarize yourself with the parts

A. Sway bar Disconnects

B. Polyurethane spacers

C. Upper posts

D. Lower post drivers side

E. Lower post passenger side

Important: Passenger side lower post is not tapered to prevent tire damage.

F. Pins

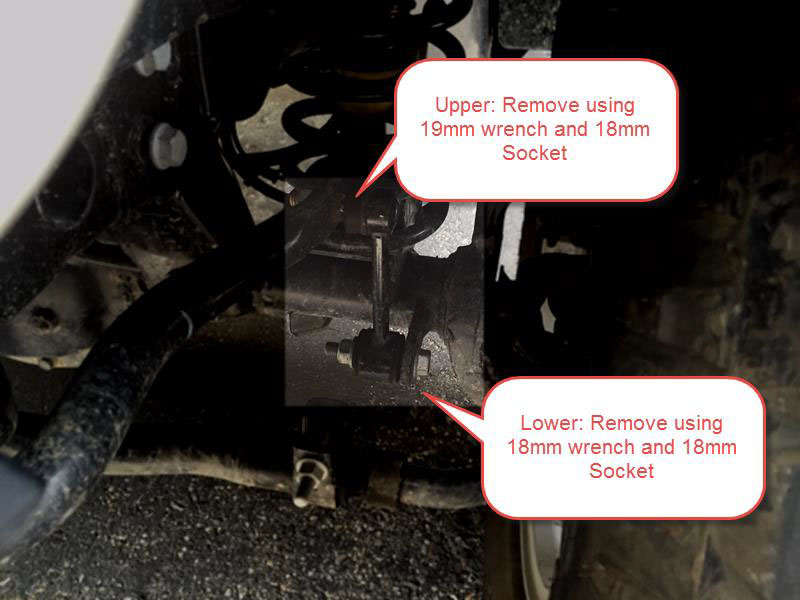

Step 2: Remove factory hardware

1. Place the vehicle on flat ground and remove driver side factory sway bar connects according to manual.

Step 3: Passenger side

Repeat Step 2 process for passenger side.

Step 4: Set aside factory hardware

1. Place factory links and bolts aside.

Step 5: Place Spacers

1. Place polyurethane spacers (Item: B) on both upper posts (Item: C) as shown in photo

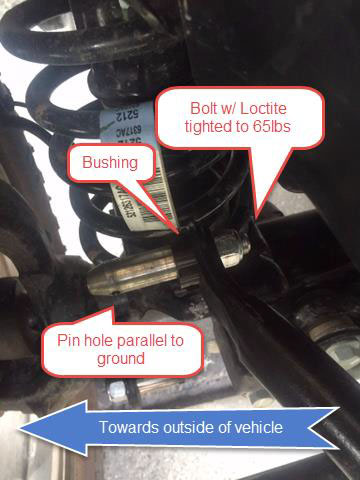

Step 6: Install upper posts (Attachment point: Sway bar)

Place upper posts (Item: C) on the outside of the sway bar so the tapered ends are pointing outwards, towards the wheel.

Keep the pin-hole in the post horizontal or parallel to the ground.

Apply a small amount of Loctite to the threads on the upper posts

Install nuts to the post and tighten to 65 ft-lb using a torque wrench

If the pin-hold tries to move, place a small #1 screwdriver or keep it parallel to the ground

Perform these steps for both sides.

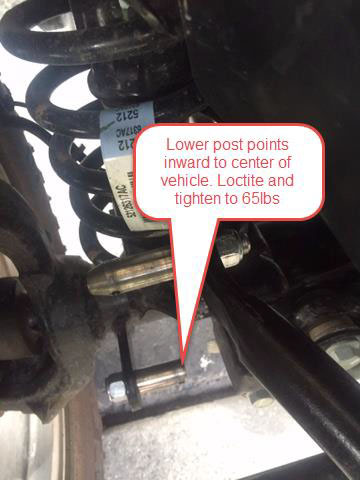

Step 6: Install lower posts (Axle Attachment)

Place posts (Item: D driver side and E passenger side) on the inside of the axle so the tapered end or pin-hold end are pointed towards the center of the vehicle. Be sure the non-tapered post is on the passenger side or risk damage to vehicle or tire.

Keep the pin-hole in the post horizontal or parallel to the ground.

Apply a small amount of Loctite to the threads on the posts

Install nuts to the post and tighten to 65 ft-lb using a torque wrench

If the pin-hold tries to move, place a small #1 screwdriver or keep it parallel to the ground

Perform these steps for both sides

Step 7: Set length of JKS sway bar links.

Using 15/16” open ended wrench, set link length. Do not exceed max length of 7-1/8” for JKS part 2030, or 11-5/8” for JKS part 2034.

Try to make the Zerk fittings face the same way so you can access them. You may choose to use the Zerk gun right now before placing them on the vehicle.

Step 8: Place JKS Disconnects

Slide the JKS disconnects on to the posts so the JKS logo is facing front of vehicle. Be sure the sway bar is horizontal.

Step 8: Install pins

Be sure the pin locks down on the post the correct way. It is important the pins fall towards the correct side and “snap” against the post. Failure to do so may cause the pin to fall out and cause serious issues.

Please ALWAYS be sure the pin snaps against the post. Before placing for the first time, experiment with the pin. See what happens when you rotate it the opposite direction and understand why this could be dangerous.

Step 9: Lubricate

1. Lubricate all Zerk fittings using a grease gun with common wheel bearing grease if you did not do so on the previous steps.

Step 10:

Installation Instructions Written by ExtremeTerrain Customer James Morris. 08/20/2015