In the good ole days, a distributor’s purpose was to ignite the air/fuel mixture using the combustion cycle. If you were to take a peek under the hood of your YJ Wrangler, you’d be sure to find one of these contraptions buried under the ignition wires.

To better understand a distributor, and how it works, let’s briefly talk about the basics.

A distributor is a mechanical device that utilizes the engine’s camshaft for operation. The camshaft rotates in conjunction with the engine’s crankshaft. As the crank turns, the camshaft opens and closes the intake/exhaust valves, which allows fuel and exhaust to flow through the engine’s cylinders.

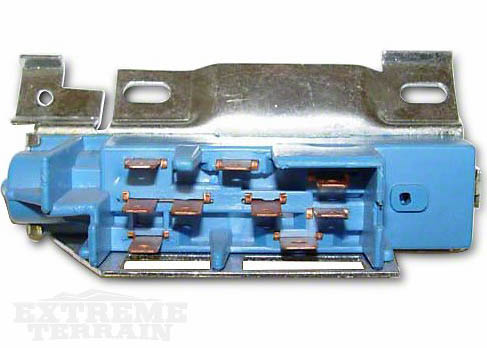

At one end of the camshaft is a gear, which engages with the distributor. As the gear on the camshaft spins, it drives the gear located at the bottom of the shaft on the distributor. This turns a rotor within the system that drags contact points along one another within the distributor cap. When these contacts points are made, electricity is sent through the spark plug wire, correlating to the piston that is reaching the top dead center and igniting the fuel.

By the time the YJ Wrangler was introduced, this system was popular for many years across all makes of vehicles. It simply worked. The ignition system had its flaws due to its mechanical nature—especially because it was dialed in by the human hand.

Understand that many things can affect how the engine runs and what it needs in order to run well.

The time of the ignition would be something subjected to adjustment in order to run right. This cap and rotor system would mean that as the distributor is set, the ignition time (whether it be advanced or retarded) would be a fixed factor across all cylinders. As each cylinder may have different requirements that could only be felt out by the operator, there’s naturally a huge opening for things to go wrong.

Then you must take into consideration some YJs arrived with a the mechanical-based carburetor. Along with having to dial in the ignition by hand, some YJ owners would also have to finely tune— by hand— the carb to find proper air/fuel ratios for optimal performance.

This style of setup, though reliable, was old and tedious. It would take trained hands, eyes and ears to make this antiquated system operate properly. Not just for initial fire up either; for true performance, the systems needed to be dialed in based on their environment. Things like atmospheric pressure can quickly affect this system's operation, requiring some intense tuning based on surroundings.

This would play a huge part in the different needs of each cylinder as they all scavenged off the carburetor through the intake manifold. The inconsistency in each cylinders amount of fuel would mean each cylinder would have different proper ignition time. It worked, but (for some!) thankfully technology consumed these tedious tasks, providing less maintenance.

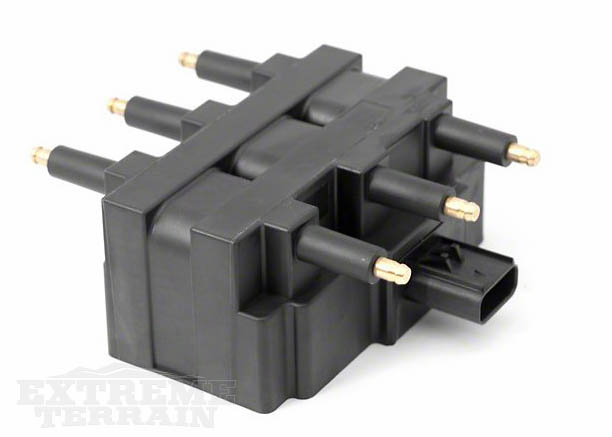

Upgrading the ignition system is incredibly simple. The first and cheapest thing you can do is upgrade the spark plugs. Moving up the list you can swap in an aftermarket ignition coil. For the really brave you can swap out the distributor itself.

The reason you would want to do any of this is to get a hotter spark to the cylinder faster. Better plugs can not only deliver a hotter spark but can also last longer. An aftermarket coil can up the voltage considerably and an upgraded distributor will more accurately and consistently send sparks. All on their own or combined will make for better performance.