The YJ Wrangler was first introduced in 1987. It was available with either a 2.5 Liter inline-4 cylinder, or a 4.0-liter inline six, and from the years 1987 through 1990 both were provided with fuel by a carburetor.

If you’re not familiar with a carburetor, it’s nothing really intimidating. A carburetor, or carb, is a mechanical device that sits on top of the engine’s intake manifold. As you press down on the accelerator, multiple things happen at once. To keep it simple, the carb opens up a butterfly valve to allow the engine to draw in more air.

Simultaneously, the fuel pump feeds fuel into the carb, where it is combined with the air to create the fuel mixture the engine needs. The carb is feeding the fuel into the intake manifold where it is then drawn into each cylinder as the intake valves open. As the intake valve opens the piston moves downward in the chamber that creates a vacuum.

Carbureted fuel systems are very common throughout the history of the automobile, and they still have their place in the world today—and probably will for a long time. It is a mechanical system that relies on vacuum and air pressure. But carbs do have some ailments. As the 80s found its place in the history books, so did the carburetor (on modern production vehicles at least.)

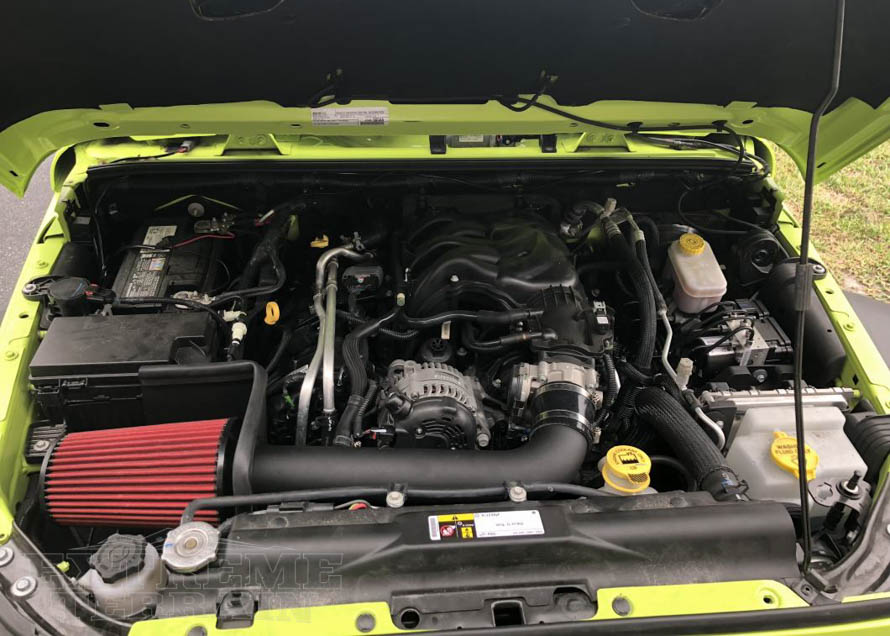

Enter the 1991 YJ. Though it is almost identical to earlier YJ Wranglers the engine were instead fed with fuel injection. Fuel injection works much the same as a carburetor. Its design is to combine fuel and air and deliver it to the engine. Though, when you pop the hood you could tell right away that there are some major differences. Instead of a single carburetor that feeds fuel and air through one opening in the intake manifold you will notice a throttle body in its place. Also, you will notice fuel injectors at the base of the runners on the intake manifold directly above each cylinder.

With a carb there’s only so much fuel and air in the manifold, and the cylinders closest to the carb tend to eat up more of this mixture than cylinders farther away. With this setup, not all cylinders are getting the same amount of gas, which obviously means there’s room for improvement. Enter fuel injection; as air moves through the body and into the intake manifold, it is drawn into each cylinder chamber. Just before it’s drawn into the chamber, a fuel injector mixes the fuel last minute making sure each cylinder is getting the appropriate amount of a fuel and air mixture.

The next biggest advantage is that after the fuel mixture is burned off, and the exhaust is sent on its way, an O2 (oxygen) sensor then picks up a reading of the exhaust and from the contents of the exhaust it can tell if the fuel mixture is too rich or too lean. With this reading the vehicle's computer system can then automatically make the proper adjustments, and you can spare yourself the time needed to dial your fuel system as you would with a carburetor.