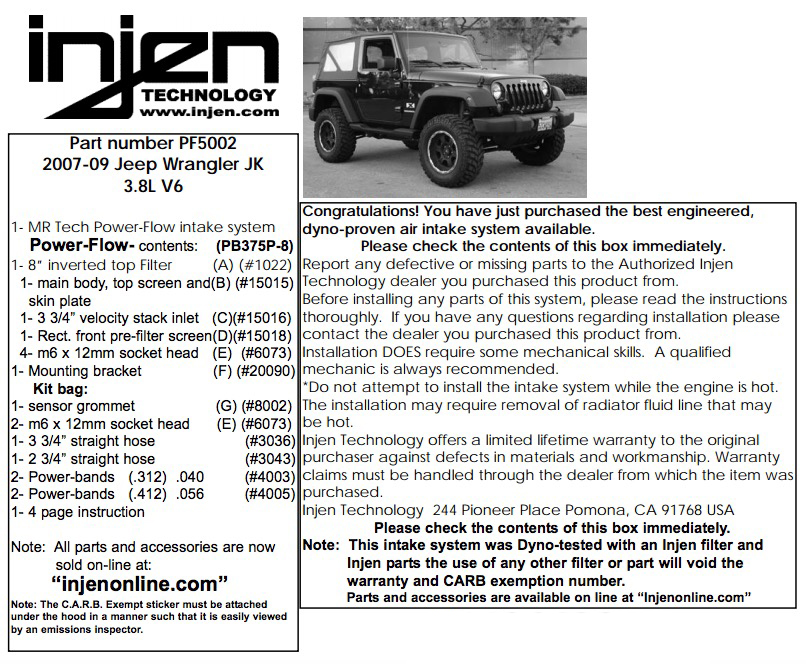

How to Install an Injen Polished Power-Flow Cold Air Intake on your 2007-2011 Jeep Wrangler JK

Shop Parts in this Guide

Stock air box and air duct to be removed.

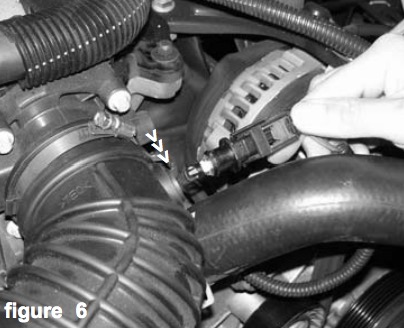

Loosen the metal clamp that secures the air duct to the throttle body

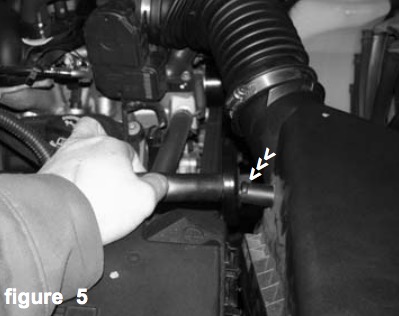

Unplug the crank case breather hose from the air box vacuum port.

Unplug the air temperature sensor from the air intake duct.

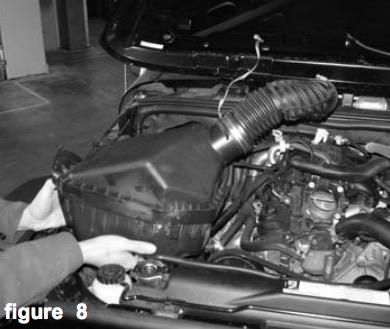

Pull the air box cleaner up and out of the stock grommets.

Pull the air duct away from the throttle body and out of the engine compartment.

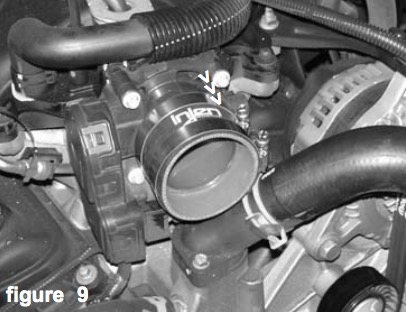

Press the 2 3/4” straight hose over the throttle body and use two power clamps. Once the straight hose has been aligned, continue to tighten the clamp over the throttle body.

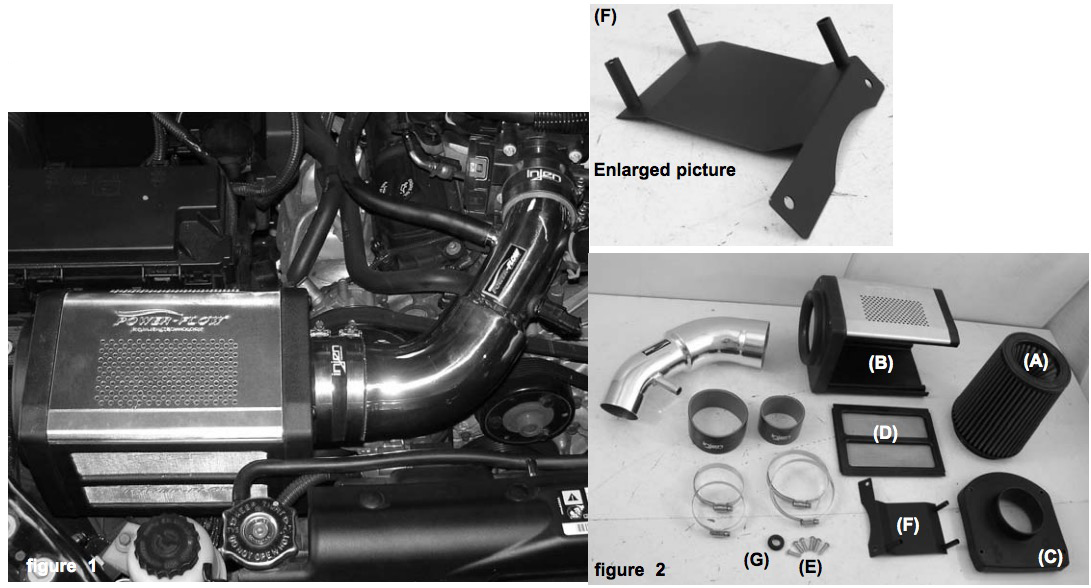

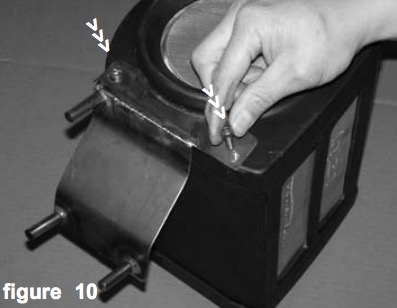

The new mounting bracket is aligned to the two bolt holes as shown above. The bracket is placed towards the front of the power box. The two m6 bolts provided in this kit are used to fasten the bracket

Use an allen wrench to tighten the allen head bolts.

Once the bracket has been installed, continue to lower the entire power box in the the engine compartment. The three metal pegs are aligned to the stock grommets and plunged into the grommets.

The three metal pegs are aligned and pressed into the stock grommets. The 3 3/4” straight hose is pressed over the the velocity stock. Two power bands are used on the hose. The clamp on the velocity stack is now tightened.

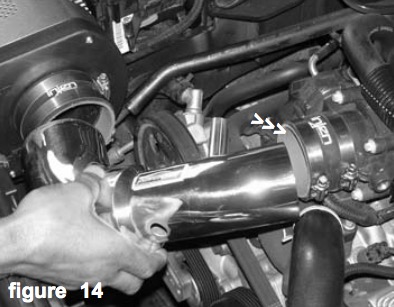

The air intake is now lowered into the engine compartment, the upper end is pressed into hose on the throttle body.

The upper end of the intake is aligned and pressed into the straight hose. The lower end is now aligned to the power box.

The lower end of the intake is now pressed into the 3 3/4” hose on the power box.

The lower end of the intake is now aligned to the straight hose. The clamps are now semi-tightened for now.

The sensor grommet is aligned to the 3/4” pre-drilled hose located on the air intake.

The grommet is pressed into the 3/4” hole until the top grommet is sitting flush to the intake contour.

The air temperature sensor is pressed into the new sensor grommet.

The air temperature sensor is sitting flush over the new grommet.

The crank case breather hose is aligned and pressed over the air intake vacuum port.

The crank case breather hose is now firmly pressed over the air intake vacuum port.

The entire intake system is aligned for best fit. Once it has been aligned,continue to tighten the clamps.

The throttle body clamps are now tightened.

All vacuums lines, sensor and hoses are now properly installed.

Check the entire air intake system for any air leaks, rattling or any loose clamps and hoses before starting the engine. Once you have check the entire system, start the engine and let it idle for 5 to 10 minutes. Allow the on-board computer to adjust to the added volume of air prior to driving.

Periodically, check the entire air intake system for any possible movement. Normal wear and tear can cause clamps and hoses to loosen over time, periodic adjustments to the intake system will enhance the life of your intake and prevent your warranty to become nolle and void.

1. Upon completion of the installation, reconnect the negative battery terminal before you start the engine.

2. Align the entire intake system for the best possible fit. Once the intake has been properly fitted continue to tighten all nuts, bolts and clamps.

3. Periodically, recheck the alignment of the intake system and make sure there is proper clearance around and along the length of the intake. Failure to follow proper maintenance procedures may cause damage to the intake and will void the warranty.

4. Start the engine and listen carefully for any odd noises, rattles and/or air leaks prior to taking it for a test drive. If any problems arise go back and check the vacuum lines, hoses and clamps that maybe causing leaks or rattles and correct the problem.

5. Check the filter for excessive dirt build up. Clean or replace the filter with an original Injen filter (can be bought on-line at “injenonline.com”).

Congratulations! You have just completed the installation of the best intake system sold on the market. Enjoy the added power and performance of your new intake system.