Top Sellers for Frontier

How to Install an Exedy Stage 2 Clutch Kit on your Jeep Wrangler

Shop Parts in this Guide

GET IT RIGHT THE FIRST TIME WHEN INSTALLING YOUR NEW EXEDY CLUTCH

1: Getting it right the first time. It is vital to diagnose the cause of clutch malfunction before clutch replacement, i.e. check the hydraulic system - bearing free travel - clutch cable, oil leaks and check for any signs of red dust when the old clutch is being removed. Any or all of these concerns must be corrected before installing the new clutch.

2: Ensure the clutch supplied is correct for the application. If you're unsure, consult the EXEDY Clutch Catalogue or your supplier, as fitting a clutch to the wrong application will void the warranty.

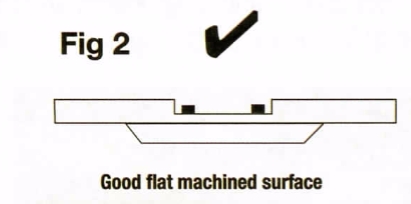

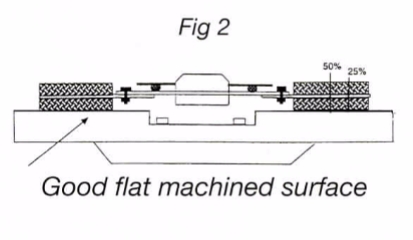

3: Flywheel must be machined as shown below (Fig 2) or the warranty will be void. Check the spigot bearing or the spigot bush and replace if necessary. Please note, pilot/spigot bush noises are more apparent when the engine and transmission systems are cold (i.e. in the morning).

4: Before fitting, check the clutch for any shipping damage. Next, clean the gearbox main drive shaft splines, and then check that the clutch disc slides freely on the shaft. Lightly grease the shaft splines with high melting point grease. Always ensure the bell housing is degreased and is free of any dust and fibres from the worn clutch are removed. If the clutch is a large size pull type, check the ID of the bearing head for the correct spline size before installation. Lack of lubrication/dry splines will cause failure to disengage gears and also cause clutch drag.

5: Check the clutch release fork for cracks, check the clutch cable for stretch signs and check the release bearing guide tube for any wear. Always lightly grease the outside diameter of the tube. This will allow for smooth sliding of the bearing carrier. Always check the bearing on the clutch release fork. Move the fork forwards and backwards (i.e. in both directions), to ensure the bearing is secure and does not foul on any part (clutch fork or bell housing) before refitting the gear box.

6: Place the clutch cover assembly over the clutch disc, after checking that the disc is the right way around (See Clutch Disc Orientation section on page 2 for further details) and ensure the hub section of the disc does not foul on the casting of the clutch cover assembly or the flywheel. A suitable clutch aligning tool will ensure the correct alignment, assist in the ease of installation and avoid spline damage (burrs on the splines can contribute to the clutch not functioning correctly). Ensure the flywheel dowels are aligned to the cover. Tighten the bolts in a diagonal pattern and never use air tools to install a clutch cover assembly. Torqueing down the bolts in an uneven pattern can cause the lever struts to dislodge, or in the case of a diaphragm cover, cause the dia-phragm fingers to be uneven.

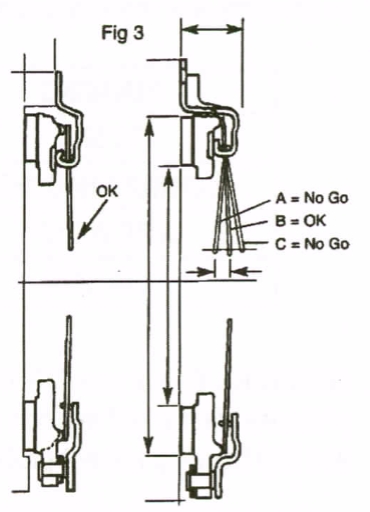

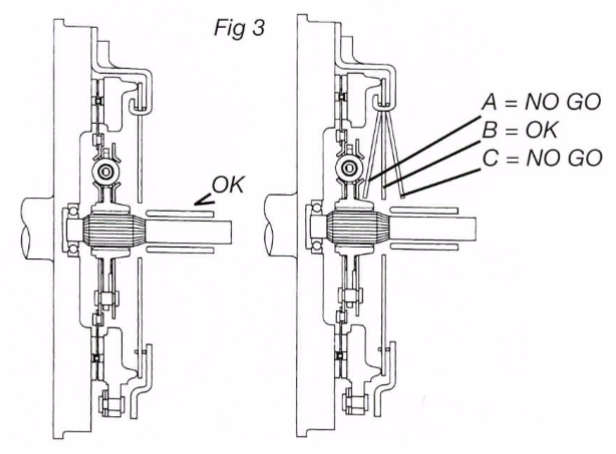

7: When the cover assembly has been torqued securely to the flywheel, ensure that the diaphragm tips (in the case of a lever type cover assembly, the release lever tips) are in a parallel position in relation to the flywheel (see Fig 3). Do not go over centre of the parallel position.

8: Re-fit the gearbox, taking care not to bend the clutch disc. Never hang the gear box on the clutch disc or use any force to align the gearbox shaft.

9: Check all bell housing dowels are in the correct position and tighten the bell housing bolts. Ensure there is no dirt or foreign material between the mating surfaces of the engine and the bell housing.

10: Perform any clutch adjustments according to the vehicle manufacturer's specifications.

11: Always check the clutch cable if you are unable to obtain disengagement when a new clutch is fitted. Start your checking process by replacing the cable. If it is a hydraulic system, check the clutch master and slave cylinder, ensuring there is no air in the system. This is essential to obtain maximum travel for disengagement.

12: Road test the vehicle and never abuse a newly fitted clutch. Allow a 1,000 km run in and always adjust the free travel on your new clutch at 1,000km and 3,000 km. Thereafter, adjust at every 10,000km.

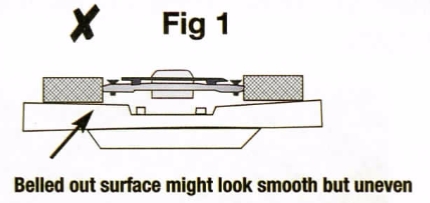

Flywheel Reclamation / Resurfacing:

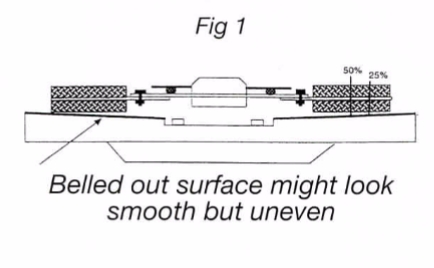

With the demise of Asbestos in the friction material used in clutches and the introduction of alternate materials, it is paramount that attention to the flywheel surface finish be maintained. To enhance the performance of the clutch and reduce the risk of shudder, the flywheel surface finish should replicate that of the pressure plate friction face of the new EXEDY cover assembly. Preferably by grinding; remove all traces of "hot spots" and/or grooving and maintain the correct flywheel profile (i.e. flat, raised or recessed). Any deviation may have a detrimental influence on the operation of the clutch.

FITTING INSTRUCTIONS: INSTALLING YOUR NEW EXEDY CLUTCH

Failure to observe these instructions when fitting your EXEDY Clutch will void any warranty.

1. How to get it right the first time.

FITTING INSTRUCTIONS: INSTALLING YOUR NEW EXEDY CLUTCH

Failure to observe these instructions when fitting your EXEDY Clutch will void any warranty.

Getting it right the first time. It is vital to diagnose the cause of clutch malfunction before clutch replacement, i.e. check hydraulic system - bearing free travel - clutch cable, oil leaks and check for any signs of red dust when old clutch is being removed. Any or all of these problems must be corrected before installing a new clutch.

2. Ensure clutch supplied is correct for the application. If you're unsure, consult your EXEDY Clutch Catalog or your supplier, as fitting a clutch to the wrong application will void the warranty.

3. Flywheel must be replaced or machined as shown below (Fig 2. max 0.03 in.) or warranty will be void and check spigot bearing or the pilot bush and replace if necessary. Please note pilot bush noises are more apparent when the engine and transmission systems are cold (i.e. in the mornings).

4. Before fitting, check the clutch for any shipping damage. Next clean the gear box main drive shaft splines, then check that clutch disc slides freely on the shaft. Lightly grease the shaft splines with high melting point grease. Always ensure bell housing is degreased and is free of any dust and that fibers from the worn clutch are removed. If the clutch is a large size pull type clutch check the ID of the bearing head for correct spline size before installation. Lack of lubrication/dry splines will cause failure to disengage gears and also cause clutch drag. Never over lubricate / grease the spline of your clutch disc as grease will splatter during rotation of the engine and clutch. Contamination — grease/oil on the clutch disc friction material will cause the clutch to slip.

5. Check clutch release fork for cracks, check the clutch cable for stretch signs and check the release bearing guide tube for any wear. Always lightly grease the outside diameter of the tube. This will allow smooth sliding of the bearing carrier. Always check bearing on clutch release fork after installing the bearing on it. Move the fork forwards and backwards i.e. in both directions, to ensure bearing is secure and does not fall on any part (clutch fork or bell housing) before refitting gear box.

6. Place the clutch cover pressure plate assembly over the clutch disc, after checking that the disc is the right way around and the hub section of the disc does not fall on the casting of the clutch cover assembly or the flywheel. A suitable clutch aligning tool will ensure correct alignment, assist in ease of installation and avoid spline damage. (Burrs on splines are a major cause of difficult gear disengagement). Ensure pressure plate dowels are aligned to the cover. Tighten bolts in a diagonal pattern and never use air tools to install a clutch cover assembly. Torquing down bolts in an uneven pattern in some instances could cause the lever strut to dislodge itself from the pressure plate casting.

7. When the pressure plate has been torqued down securely to the flywheel, ensure that the diaphragm tips (in the case of a lever type cover assembly, the release lever tips) are in a parallel or slightly upward position (see Fig 3) and do not go over center of the parallel position.

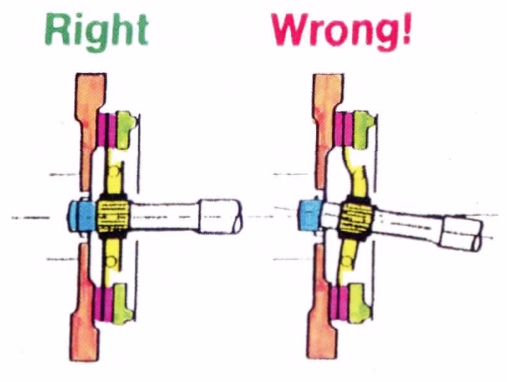

8. Refit gear box, taking care not to bend the clutch disc. Never hang the gear box off the clutch disc or use any force to align gear box shaft.

9. Check all bell housing dowels are in correct position and tighten bell housing bolts. Ensure there is no dirt or foreign material between the mating surfaces of the engine and the bell housing.

10. Perform any clutch adjustments to vehicle manufacturer's specifications and always reset the clutch master cylinder push rod to obtain comfortable pedal release position (clutch taking up as close as possible to the floor prevents clutch shudder and in most cases preferred by vehicle drivers). Keep in mind that the diaphragm tip position has changed with the installation of the new clutch.

11. Always check the clutch cable if you are unable to obtain disengagement when a new clutch is fitted. Start off your checking process by replacing the cable. If it is a hydraulic clutch start by checking the clutch master cylinder and the clutch slave cylinder, ensuring there is no air in the system. This is essential to obtain maximum travel for disengagement.

12. Road test vehicle and never abuse a newly fitted clutch. Allow 750 mi break in and always adjust free travel on your new clutch at 750 mi and 1500 miles. Thereafter, adjust at every 10,000 miles.

WARNING: Do not use EXEDY clutches in any situation where engine RPM's may exceed manufacturer's specifications - a pressure plate could explode unexpectedly causing serious injury or death to vehicle occupants and bystanders. Clutch cover and bell housing will not protect against exploding pressure plates. Refer to the Application Catalogue for correct fit.

For performance/sport applications always use an EXEDY sports replacement clutch.

Diagnosing Bearing Noises

1. Clutch release bearing

A. Depress the clutch pedal approximately 2". the bearing is now in contact with the diaphragm. Should the bearing rumble or squeal then the clutch release bearing is most likely at fault (providing it has been pressed onto the carrier the right way around.)

2. Pilot Bearing or Bush.

A. With engine running depress the clutch fully.

B. Select first gear.

C. Release the clutch.

If the squeal is heard at the point of the clutch taking up, then the pilot bearing is faulty. In the event it is a bronze bush it will indicate lack of lubrication on the I.D. of the bush. If the bush has been lubricated on the I.D. there is a greater possibility that the O.D. of the bush is under sized and worn. The noise is then caused by the bush spinning in the end of the crank. If new pilot bush has not been pressed in evenly this could also result in the bush spinning which would cause a grumbling or squealing noise. Pilot bush noises are more apparent when engine and transmission are cold. (i.e. In the morning).

3. Front gear box bearing

A. Drive the vehicle at approximately 25 mph in gear. If a noticeable grumble noise is apparent, depress the clutch pedal to the floor. This will, in turn, stop the main drive and bearing from spinning. If noise ceases it is probable that the front gear box bearing is faulty (as there is no load on the bearing).

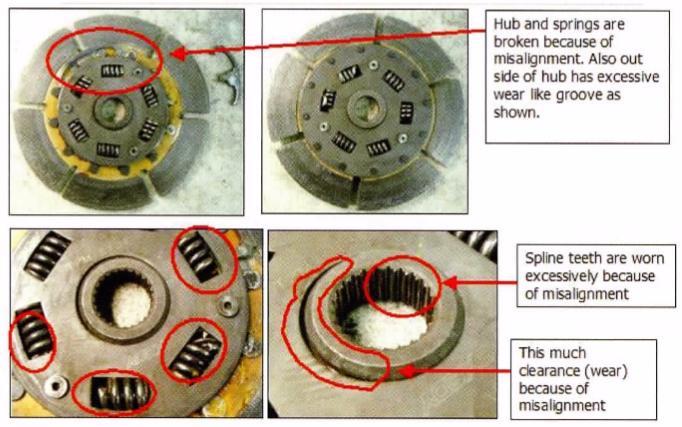

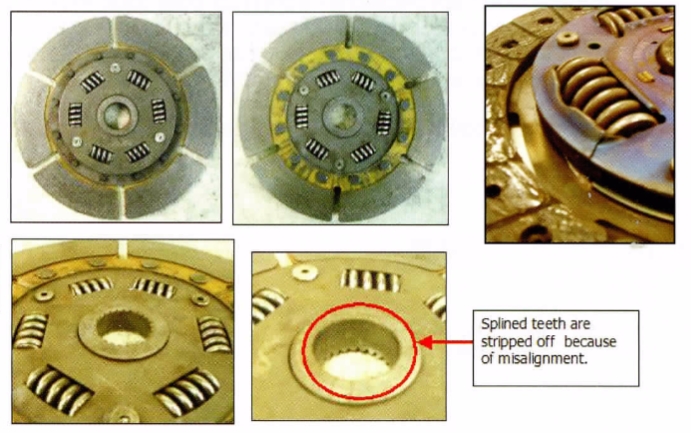

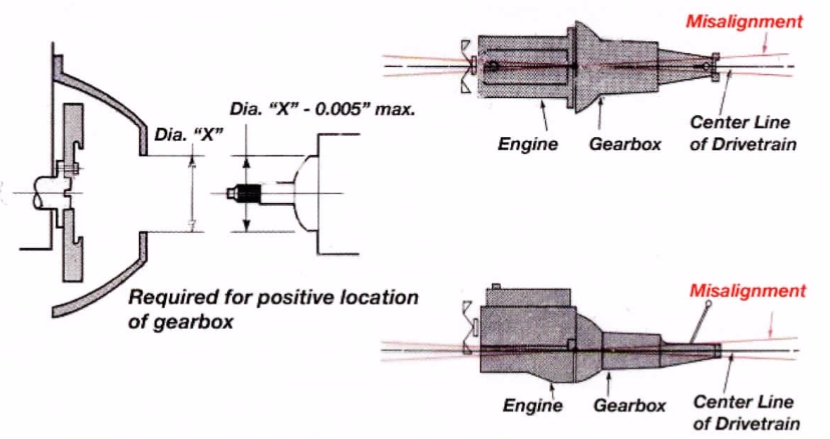

General Misalignment Issues/Tips

1. Check for a warped alloy bell housing

2. Examine tubular dowel pins for damage during fitting of bell housing or for missing dowel pins.

3. Examine gearbox quill/gearbox main drive nose cone/bearing slide: Excessive wear can cause bearing to come in contact with the cover assembly diaphragm unevenly while actuating the clutch.

4. Ensure the proper mating of bell housing to motor, and crankshaft to flywheel. These may not mate properly due to debris, grease or other parts in the way of the mating surfaces.

5. Examine all bearings/bushings for excessive wear, replace if necessary.

6. Replacement engines and gearboxes may have missing dowel pins. Ensure that you remove pins from your product when you send your core for remanufacture, and refit or replace them when installing new clutch.

Hanging the Gearbox

Examples of Common Warranty Exclusions