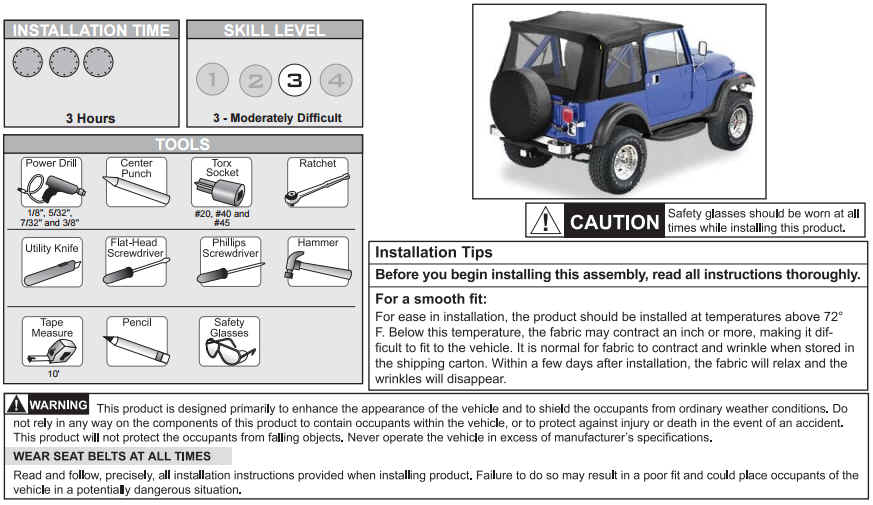

How to Install a Bestop Supertop on your 1987-1995 Jeep Wrangler

Installation Time

3 hours

Tools Required

- Power Drill

- Center Punch

- Torx Socket

- Ratchet

- Utility Knife

- Flat-Head Screwdriver

- Phillips Screwdriver

- Hammer

- Tape Measure

- Pencil

- Safety Glasses

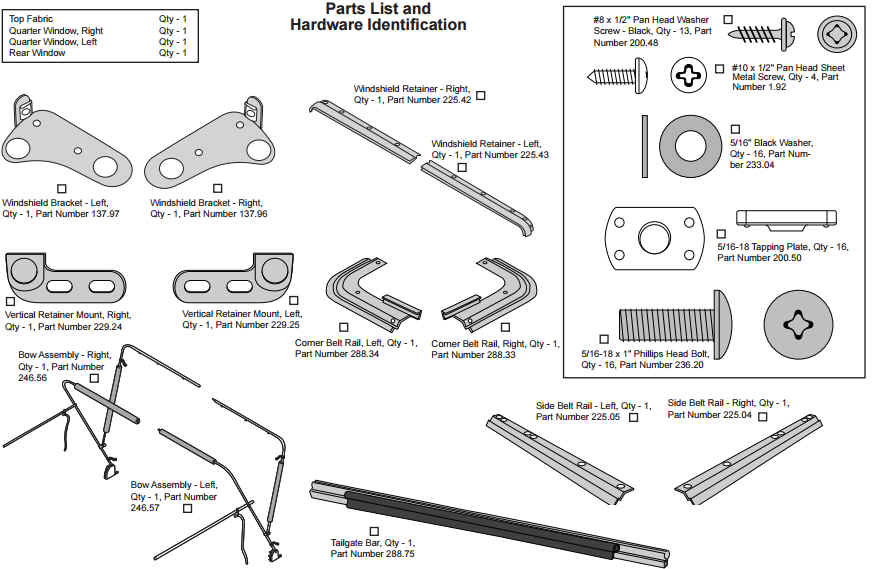

Shop Parts in this Guide

NOTE

If you are replacing an old soft top, be certain that all parts of the old top are removed, including the windshield retainer. Old metal parts are not compatible with the new Supertop. Using parts other than those provided in your Supertop kit can result in personal injury and/or damage to the vehicle and soft top.

WARNING

Improper windshield adjustment will result in poor fitting top and doors, causing looseness or undue strain on the top

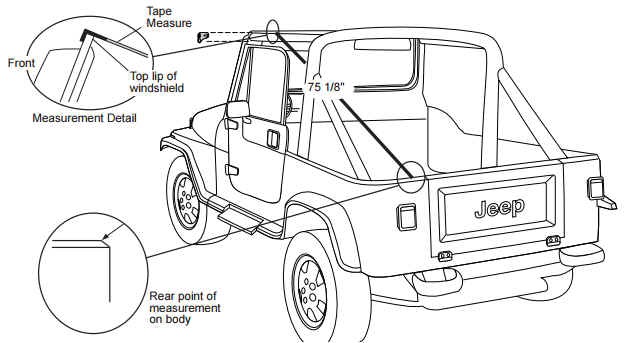

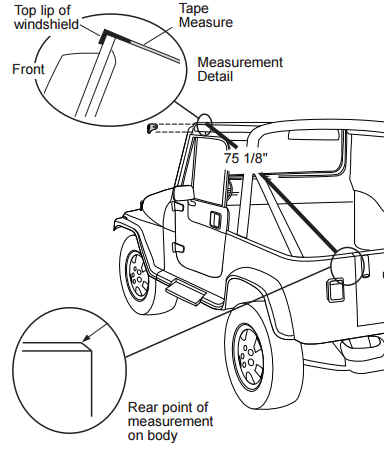

CJ7 Windshield Measurement

Before installing the top, check the windshield measurement. The distance from the top lip of the windshield to the top outer edge of the body must be 75 1/8" on both sides of the vehicle. Measure from 6" inside the doors.

CJ7 Windshield Adjustment:

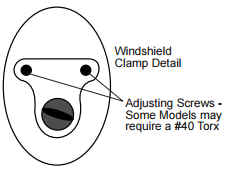

If necessary, loosen the two screws in the Windshield Clamps at the base of the windshield on each side of the vehicle. Adjust the windshield forward or back, use a shim if needed to position the windshield, and tighten the screws.

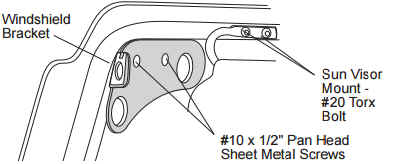

1 Install Windshield Brackets – CJ7 Only

After adjusting the windshield, install the Windshield Brackets. If present remove the outboard sun visor fasteners on both sides of the windshield frame. Place the Windshield Brackets flush with the frame on the upper corners of the windshield. Use the bracket as a template to mark, center punch and drill two 5/32" holes for each bracket. Mount each bracket to the windshield frame using two #10 x 1/2" Pan Head Sheet Metal Screws. Reinstall sun visor brackets

NOTE

Under most circumstances, the windshield of the Wrangler will not require any adjustment. If your Wrangler windshield should require adjustment, this adjustment should be performed only by an authorized automotive mechanic using a special "Tamper-Proof" Torx head tool.

WARNING

Improper windshield adjustment will result in poor fi tting top and doors, causing looseness or undue strain on the top

Wrangler Windshield Measurement

Before installing the top, check the windshield measurement. The distance from the top lip of the windshield to the top outer edge of the body must be 75 1/8" on both sides of the vehicle. Measure 4"-6" inside the doors.

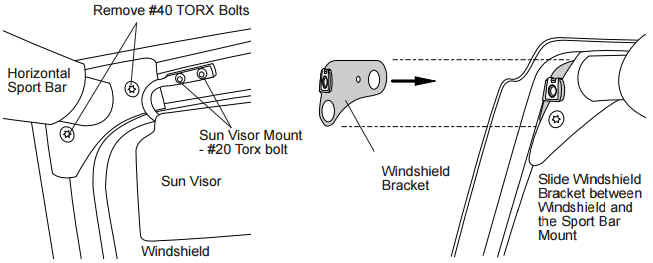

Wrangler/YJ Windshield Adjustment

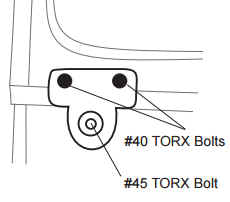

If necessary, loosen the #40 TORX bolts in the windshield clamps to loosen the windshield in order to slip the bracket under the horizontal tube.

WARNING

Reinstall the bolts that secure the Horizontal Sport Bars to the windshield with a torque of 17.0 ft. lbs. each. If you do not have a torque wrench these bolts should be tested by a qualifi ed mechanic using a torque wrench. Failure to tighten and test the torque of these bolts can result in personal injury or loss of life to the driver and occupants of the vehicle in the event of an accident.

1 Install Windshield Brackets – Wrangler/YJ Only

Use a #20 Torx to remove the outboard sun visor fasteners on both sides of the windshield frame. Remove the two #40 Torx head bolts that secure the horizontal sport bar to the windshield frame. Slide the Windshield Brackets between the windshield and the horizontal sport bar mounts. Reinstall the Torx head bolts, starting each in the frame with your fi ngers. After the Torx head bolts are started by hand tighten with your rachet and Torx drive tool. Do not lay this tool aside until both bolts are completely tightened. If you tighten one of these bolts and the telephone rings - LET IT RING. NEVER LAY THIS TOOL ASIDE OR INTERUPT THIS PROCEDURE. This procedure should be followed carefully on both sides of the vehicle.

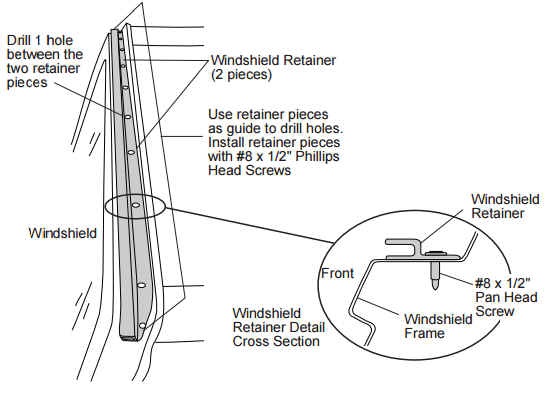

WARNING

A loose Windshield Retainer may allow the top to disengage from the windshield, causing damage to the top and possible injury to the occupants of the vehicle. Make certain that the Windshield Retainer is securely fastened to the windshield during installation and at all other times by checking the tightness of the mounting screws every three months. Do not use any drill size other than 1/8". Failure to use the correct size may cause the Windshield Retainer to loosen.

2 Install Windshield Retainer

Position the two piece Windshield Retainer on top of windshield frame. Use retainer pieces as templates to mark, center punch and drill eleven 1/8" holes. Install with eleven #8 x 1/2" Pan Head Screws.

CAUTION

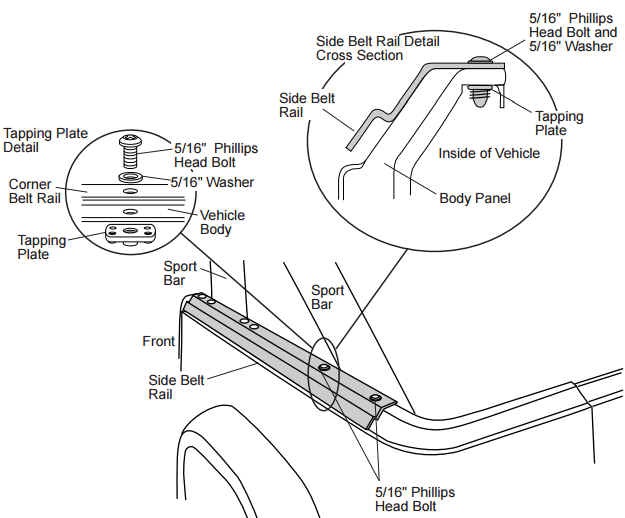

When drilling in the top edge of the vehicle body, check underneath for wiring for the rear lights. Pull the wiring out of the way before drilling.

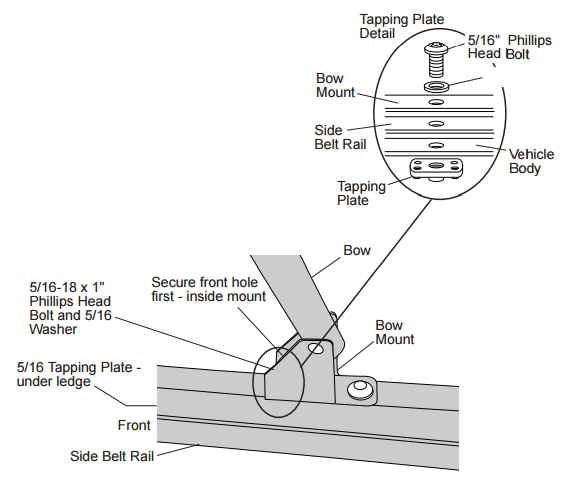

3 Install Side Belt Rails

Install the Left and Right Side Belt Rails on each side of the vehicle. Use the Belt Rails as templates to mark, center punch and drill six 3/8" holes along the top edge of the body on each side of the vehicle. Secure the two rear holes in the rails with two 5/16" Phillips Head Bolts, two 5/16" Washers and two 5/16" Tapping Plates. Do not tighten the bolts yet.

CAUTION

When drilling in the top edge of the vehicle body, check underneath for wiring for the rear lights. Pull the wiring out of the way before drilling.

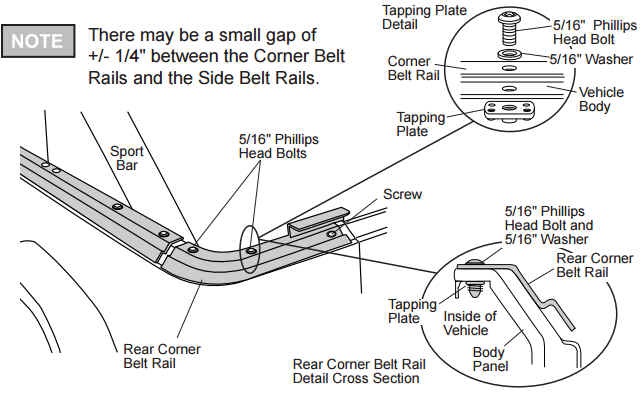

4 Install Rear Corner Belt Rails

Install the Left and Right Rear Corner Belt Rails on each side of the vehicle. Notice that the Corner Belt Rails do not butt-up against the Side Belt Rails installed in Step 3, this is normal. Use the Corner Belt Rails as templates to mark, center punch and drill two 3/8" holes in the top edge of the vehicle body. Some vehicles may already have some of these holes. Install the Corner Belt Rails with two 5/16" Phillips Head Bolts, two 5/16" Washers and two 5/16" Tapping Plates. At the location of the remaining hole in the Corner Belt Rail, next to the tailgate, mark, center punch and drill a 1/8" hole. Install a #8 x 1/2" Pan Head Screw. Do not tighten the bolts yet.

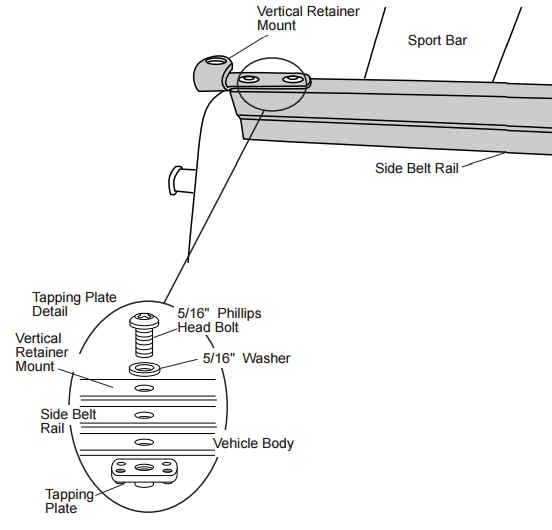

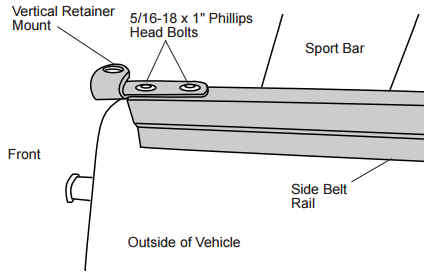

5 Install Vertical Retainer Mounts

Install the Vertical Retainer Mounts on top of the Side Belt Rails, just behind the door openings. Secure them in place with two 5/16-18 x 1" Phillips Head Bolts, two 5/16" Washers and two 5/16" Tapping Plates. Do not tighten the bolts yet.

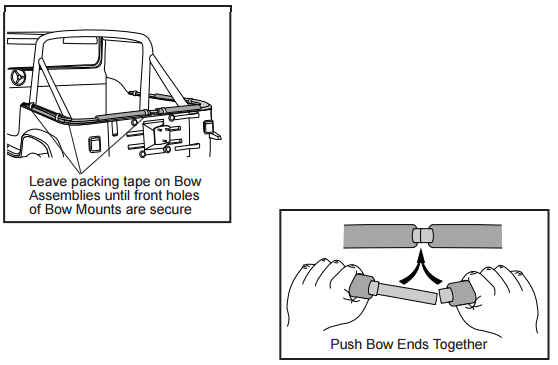

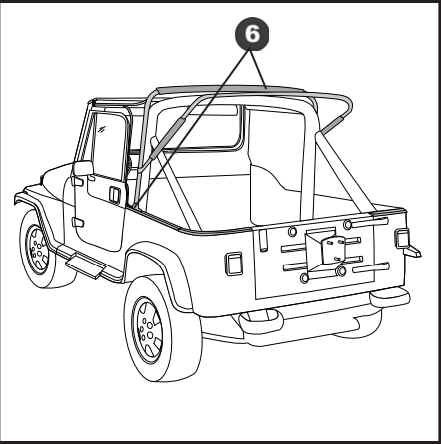

6 Install Bow Assembly

Lay the bow halves on top of the body with the holes in the Bow Mounts over the third and fourth holes in the Side Belt Rails.

It is important that the white packaging tape remain on the bow assemblies until the forward bolt is tightened on both sides.

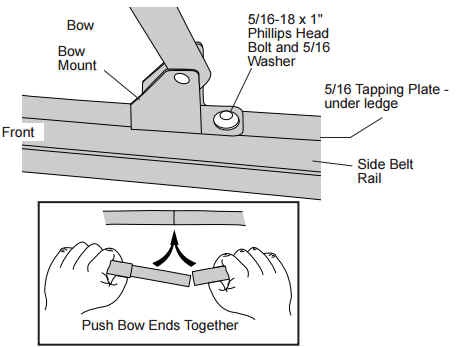

Secure the FRONT hole in the Bow Mount with a 5/16-18 x 1" Phillips Head Bolt, a 5/16" Washer and a 5/16" Tapping Plate. Once the front hole is secure, cut the packing tape. Start the male end of the Top (Front) Bow into the female end. Push forward on the bow until the two sides snap together. Slide the foam pieces on the bow together.

Once the Bow Mounts are secure, tighten all of the bolts on the Belt Rails.

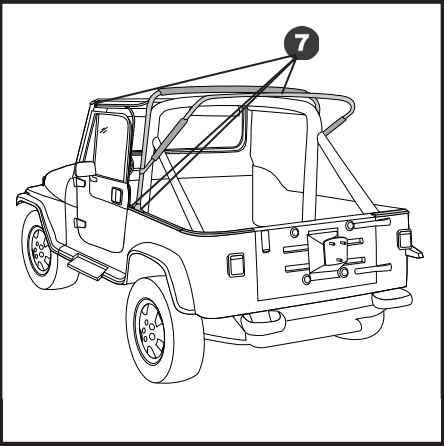

7 Install Bow Assembly

Release the small metal rods from the plastic clips on both sides of the vehicle.

Lift the Top (Front) Bow and start the male end of the Bottom (Rear) Bow into the female end. Push forward on the bow until the two sides snap together.

Slide the Bottom (Rear) Bow up on the Top (Front) Bow to access the rear bolt position in the Bow Mount. Install and tighten the rear bolt in the Bow Mount on both sides of the vehicle.

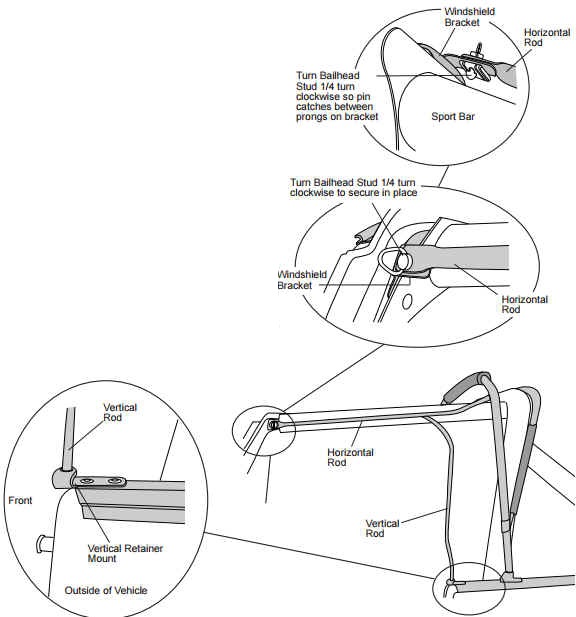

Raise the Top (Front) Bow Assembly, holding the small rods in an upright position, and insert the Vertical Rods into the hole in the Vertical Retainer Mount. Attach the Horizontal Rod to the Windshield Bracket using the Bailhead Stud. The pin on the Bailhead Stud will only turn clockwise because of the prongs on the edges of the opening in the Windshield Bracket. Slip the pin through the opening and turn the Bailhead Stud a quarter turn clockwise so that the fl anges on the pin are secure between the prongs.

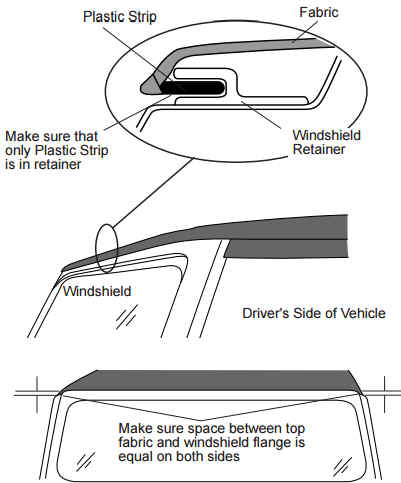

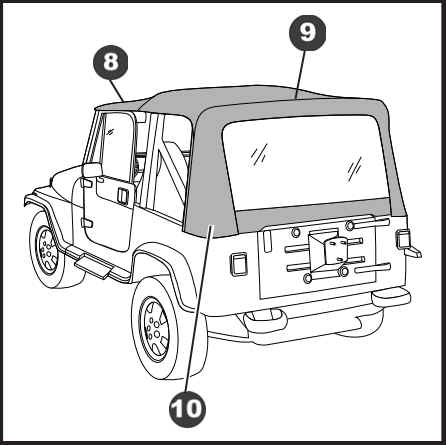

8 Install Top on Vehicle

Locate the top and orient it on the vehicle. Drape the top over the bows and insert the plastic strip sewn along the front of the top into windshield retainer attached on the front of the windshield frame. Center the front of the deck on the vehicle so that it is an equal distance from the top of the windshield fl ange on both sides.

NOTE: For best possible installation, check to make sure that the soft top is perfectly centered on the vehicle.

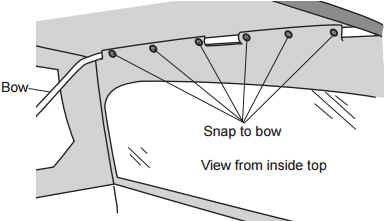

9 Snap Top to Rear Bow

Snap the flaps to the six studs on the rear bow.

NOTE: If the snaps don't appear to line up, push the rear bow forward to relieve the pressure on the bow. This will allow the snaps to line up more easily.

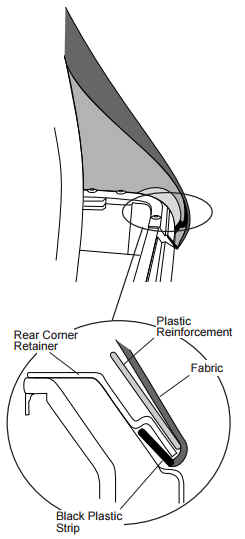

10 Secure Rear Corners

Insert the black plastic strips at rear corners of top into Corner Belt Rails. There is a plastic reinforcement sewn into the corner of the top, in addition to the plastic strip.

Make sure that the reinforcement is not caught under the Corner Belt Rail.

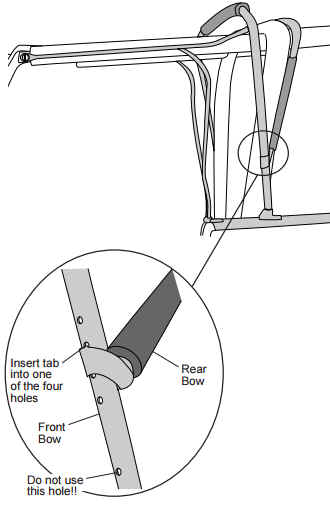

11 Raise the Rear Bow

Slide the Rear Bow up on the Front Bow and insert the small bent tab into one of the four holes in the Front Bow. Rear Bow Front Bow.

NOTE: If the top is extremely tight, slip the tab into the bottom hole. The top will loosen up after a few hours in the sun. Then the tab may be inserted into a higher hole position.

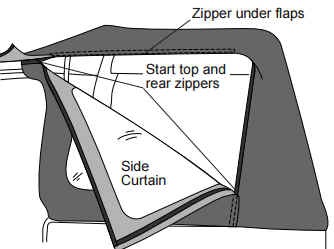

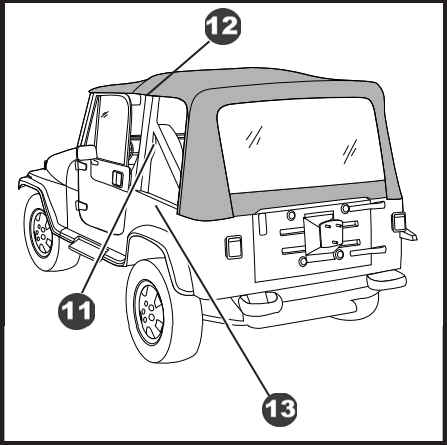

12 Install Side Curtain

Start top and rear zippers on side curtain 6 inches.

NOTE: If necessary, release the Bow Coupler and slide the top around the Corner Belt Rail towards the window to make it easier to start the zippers on the Side Curtains.

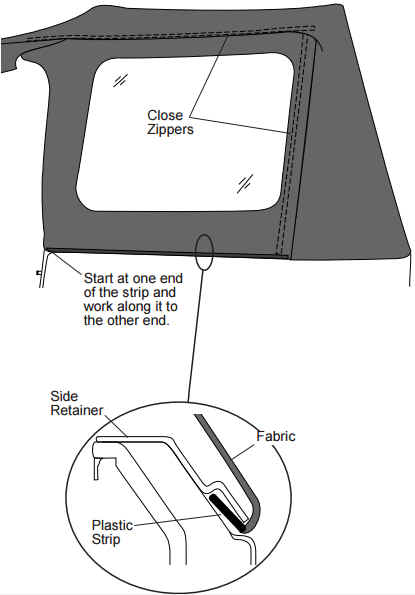

13 Secure Bottom of Side Curtain

Slip the plastic strip on the bottom of the side curtain into the side retainer. Close the top zipper on the side curtain.

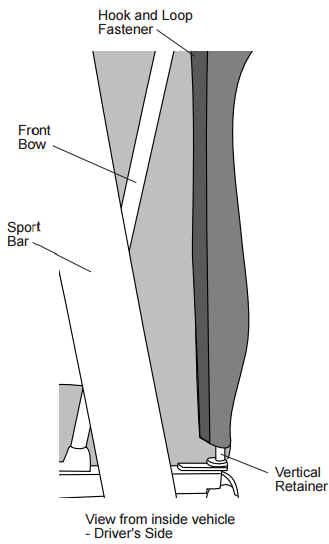

14 Secure Front of Side Curtain

Wrap fabric flap on the front of the side curtain around the Vertical Rod (not the front bow) and fasten the hook and loop strips to each other.

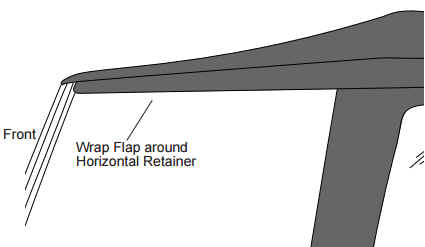

15 Secure Door Flaps

Wrap the flap, sewn to the top above each door, around the Horizontal Rod and fasten the hook and loop strips to each other.

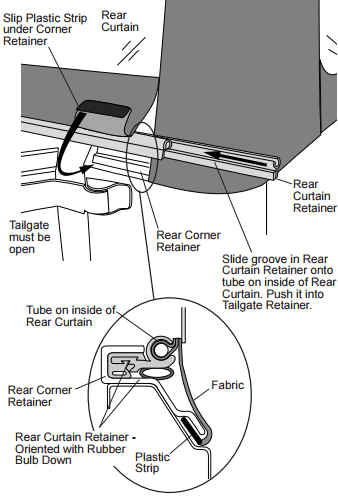

16 Install Rear Curtain Retainer

Open the tailgate. Orient the Rear Curtain Retainer with the rubber bulb facing down, in order to form a seal with the top of the tailgate. Slide the groove in the Rear Curtain Retainer onto the tube inside the bottom of the Rear Curtain. Roll the Rear Curtain Retainer into the top of the Corner Belt Rail. Slip the plastic on the bottom of the corners under the bottom of the Corner Belt Rail. Close the rear curtain zippers.

NOTE

Now that your soft top is fully installed there are some final Metal Door adjustments that may need to be made to give you the best weather seal possible.

WARNING

If any of these adjustments are made, make sure that each area has been retightened. Each area should be rechecked within a week to assure proper fit and function.

17 Adjusting Vertical Retainer

The Verticle Retainer mount may be loosened and moved either forward or to the rear of the vehicle to tighten the seal or to allow more clearance.

WARNING

When operating the vehicle without the Side Curtains, the Rear Curtain should be rolled up for proper ventilation.

18 Adjusting the Top

Side Curtains

To remove the Side Curtains. Unzip the rear and top zippers. Release the plastic strip from the retainer. Release the Hook and Loop Fasteners from around the Vertical Retainer.

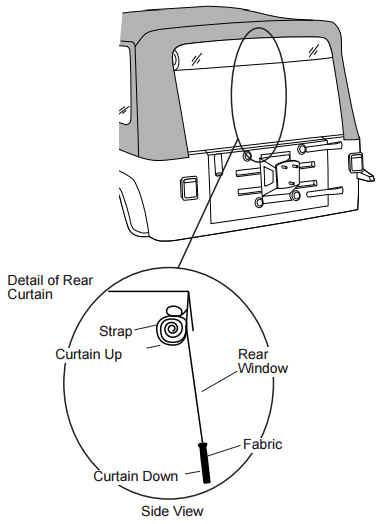

Rear Curtain

To roll up the Rear Curtain, remove the Rear Curtain Retainer and start at the bottom, rolling it to the inside. Avoid wrinkles in the fabric and window. Secure it in place with the curtain straps inside of the top.

19 Folding the Top Down

Open the zippers at the rear of the Side Curtains. Pull the plastic strip on the bottom of the Side Curtains out of the Belt Rails. Leave the rear corners of the top attached to the Corner Belt Rails. Unfasten the hook and loop strips at the front of the Side Curtains, releasing the Side Curtains from the Vertical Retainer. Fold the Side Curtains up onto the top and release the hook and loop fasteners on the fl aps, above the doors. Unsnap the top from the rear bow.

Release the locking tabs on the Bow Releases from the holes in the bow and slide the rear bow down to the Bow Mounts. Release the Horizontal Rod from the Windshield Bracket. Remove the Vertical Rod from the Vertical Retainer Mount and lay the bow assembly down on the rear of the vehicle.

Unfasten the top from the windshield and lay it down on the body. Make sure that the rear corners of the top are tucked under the rear bow. Fold the top in half from front to back and continue folding until the top is about 1 foot wide at the rear of the vehicle. Secure the top by clipping the Bow Tie Downs into the Side Belt Rails.

20 Removal of Soft Top for Open Air Driving

When operating the vehicle with the fabric top removed, it is very important that the supporting hardware system be disconnected from the windshield bracket and folded fl at to the rear of the vehicle. The vertical and horizontal rods should be snapped into the plastic clips located on the inside of both bow mount brackets. Wrap the elastic straps around the bows and insert the plastic strip into the side belt rail. Never operate the vehicle with the fabric removed and the hardware in the fully erected position.

Care and Maintenance of your Bestop Product

Your Bestop product is made of the fi nest materials available. To keep it looking new and for the maximum possible wear, it will need periodic cleaning and maintenance.

Fabric: The fabric should be washed often using soap, warm water and a soft bristle brush. Rinse with clear water to remove all traces of soap or use Bestop-recommended Bestop Cleaner and Bestop Protectant. Bestop Cleaner and Bestop Protectant are specially formulated to provide a total cleaning and protection system. Bestop Cleaner will not harm vehicle finish, is biodegradable and environmentally friendly. Bestop Protectant protects against UV-fading, cracking and hardening.

Windows: Keep windows clean to avoid scratching. DO NOT use a brush on the windows! Wash with a water-soaked cloth or sponge and a mild dishwashing detergent or use Bestop-recommended Bestop Vinyl Window Cleaner, which safely cleans and protects vinyl windows while helping prevent UV damage. NEVER WIPE THE WINDOWS WHEN THEY ARE DRY. Be careful when cleaning snow or frost from the vinyl windows since they are easily scratched and may crack at low temperatures. DO NOT roll the sides or rear window in cold weather. The windows become stiff and will crack. Cracks caused by misuse in cold temperatures are not covered under warranty.

Zippers: Keeping the zipper cleaned and lubricated with a silicone lubricant will help prevent damage and keep the zippers in a smooth working condition. If a zipper opens behind the slider, the slider may have been spread apart. This problem can usually be repaired by using an ordinary pair of pliers to bring the sides back into parallel. Return slider to the end of the zipper in the normal Open position. Squeeze lightly at fi rst and test the zipper. If the zipper continues to remain open squeeze more fi rmly with the pliers and try the zipper again. Repeat this procedure until the zipper operates correctly.

Water: Seeping through at the seams may be stopped by applying 3-M Scotchgard® on the inside of the seams. Rips in the fabric may be repaired with Bondex® iron on patches. Iron the patches to the Inside of the top, carefully following the Bondex® instructions.

Snaps: Keep snaps cleaned and lubricated with silicone to help prevent snaps from sticking to the studs. If a snap does become stuck to a stud, use a screwdriver and GENTLY pry apart to prevent permanent damage to the snap or the top fabric.

LIMITED WARRANTY

We warrant our product to be free from defects in material and workmanship, for the terms specified below, provided there has been normal use and proper maintenance. This warranty applies to the original purchaser only. All remedies under this warranty are limited to the repair or replacement of any item or items found by the factory to be defective within the time period specifi ed. If you have a warranty claim, first you must call our factory at the number below for instructions. You must retain proof of purchase and submit a copy with any items returned for warranty work. Upon completion of warranty work, if any, we will return the repaired or replaced item or items to you freight prepaid. Damage to our products caused by accidents, fire, vandalism, negligence, misinstallation, misuse, Acts of God, or by defective parts not manufactured by us, is not covered under this warranty.

THE WARRANTY TIME PERIOD IS AS FOLLOWS FOR REPLACE-A-TOP™, SAILCLOTH REPLACE-A-TOP™, SUPERTOP®, SUPERTOP® REPLACEMENT SKINS, SUNRIDER®, AND TIGERTOP®: TWO YEARS FROM DATE OF PURCHASE. THE WARRANTY TIME PERIOD IS AS FOLLOWS FOR ALL OTHER “SOFT GOODS” MANUFACTURED BY OUR COMPANY (USING PRIMARILY VINYLS, PLASTICS, AND/OR FOAM): ONE YEAR FROM DATE OF PURCHASE. THE WARRANTY TIME PERIOD IS AS FOLLOWS FOR ALL OTHER “HARD GOODS” MANUFACTURED BY OUR COMPANY (USING PRIMARILY METALS, PLASTICS, AND/OR FIBERGLASS): ONE YEAR FROM DATE OF PURCHASE. ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR PURPOSE CREATED HEREBY ARE LIMITED IN DURATION TO THE SAME DURATION AND SCOPE AS THE EXPRESS WRITTEN WARRANTY. OUR COMPANY SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGE.

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion or limitation of incidental or consequential damages, so the above limitations or exclusions may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

For further information or request for warranty work, please contact:

Bestop Inc.,

Customer Service

Toll-Free: (800) 845-3567

Main: (303) 465-1755

E-mail: [email protected]

Website: www.Bestop.com