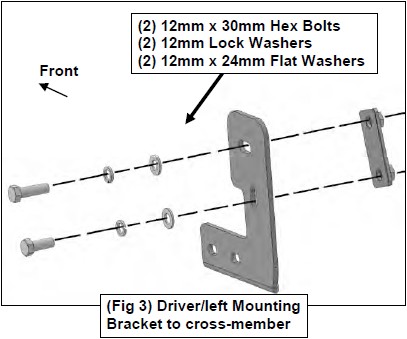

How to Install Barricade HD Bull Bar w/ Skid Plate & 20 in. LED Dual-Row LED Light Bar - Textured Black on your Wrangler

Shop Parts in this Guide

PROCEDURE:

1. REMOVE CONTENTS FROM BOX. VERIFY ALL PARTS ARE PRESENT. READ INSTRUCTIONS CAREFULLY. CUTTING IS REQUIRED. ASSISTANCE IS RECOMMENDED.

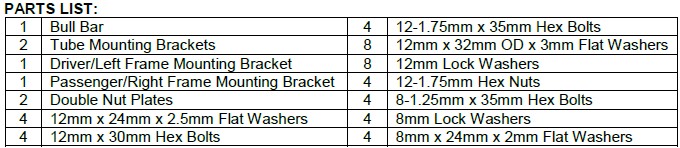

2. Remove the plastic splash guard from under the front bumper and place it on a clean, stable work surface, (Figure 1).

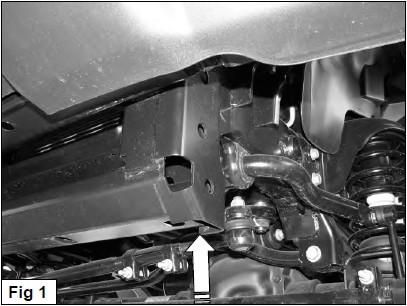

3. Starting on the driver side, insert (1) 12mm Double Nut Plate, (Figure 2), into the opening in the end of the frame cross-member. Line up the lower hole in the Nut Plate with the lower hole in the frame.

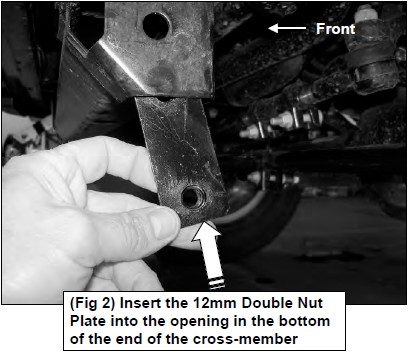

4. Select the driver side Mounting Bracket. Insert (1) 12mm x 30mm Hex Bolt, (1) 12mm Lock Washer and (1) 12mm x 24mm Flat Washer through the lower hole in the Bracket, cross-member and into the Double Nut Plate, (Figure 3). Leave hardware loose at this time.

5. Repeat Steps 3-4 for passenger side Mounting Bracket installation.

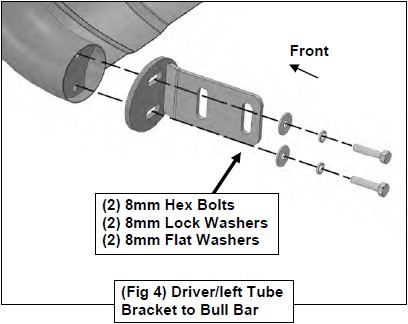

6. Place Bull Bar on a clean, stable work surface. Select the passenger side Bull Bar Tube Bracket. Bolt the Bracket to the end of the Bull Bar with (2) 8mm Hex Bolts, (2) 8mm Lock Washers and (2) 8mm Flat Washers, (Figure 4). Snug but do not tighten hardware. Repeat this Step for driver side Bracket.

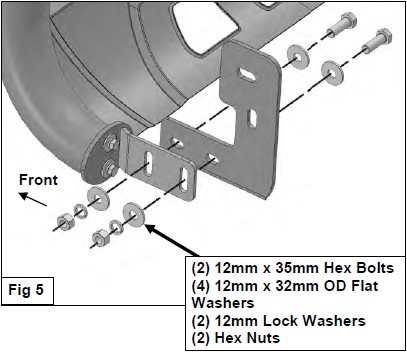

7. With assistance, hold the Bull Bar with Brackets up in position on the inside of the Frame Mounting Brackets. Attach the Bull Bar to the Brackets with (4) 12mm x 35mm Hex Bolts, (8) 12mm x 32mm OD Flat Washers, (4) 12mm Lock Washers and (4) 12mm Hex Nuts, (Figure 5). Do not tighten hardware.

8. Align the Bull Bar properly and fully tighten the Bracket hardware securing the Brackets to the frame only. Temporarily remove the Bull Bar.

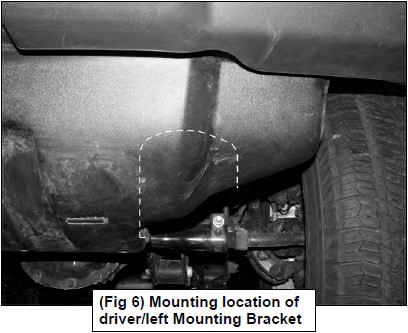

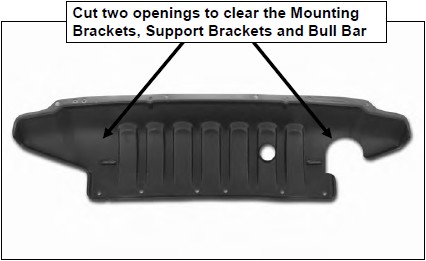

9. Position the splash guard back up to the vehicle and attach with the factory hardware. Trace the location of the Mounting Brackets onto the splash guard, (Figure 6). NOTE: Remove only material necessary to clear the Bull Bar and Brackets. Make small cuts and check the fit often before final installation, (Figure 7). Reinstall the splash guard with factory hardware.

10. Reinstall the Bull Bar and tighten all hardware.

11. Do periodic inspections to the installation to make sure is secure and tight.

To protect your investment, wax this product after installing. Regular waxing is recommended to add a protective layer over the finish. Do not use any type of polish or wax that may contain abrasives that could damage the finish. For stainless steel: Aluminum polish may be used to polish small scratches and scuffs on the finish. Mild soap may be used also to clean the Bull Bar.

For gloss black finishes: Mild soap may be used to clean the Bull Bar.

PROCEDURE:

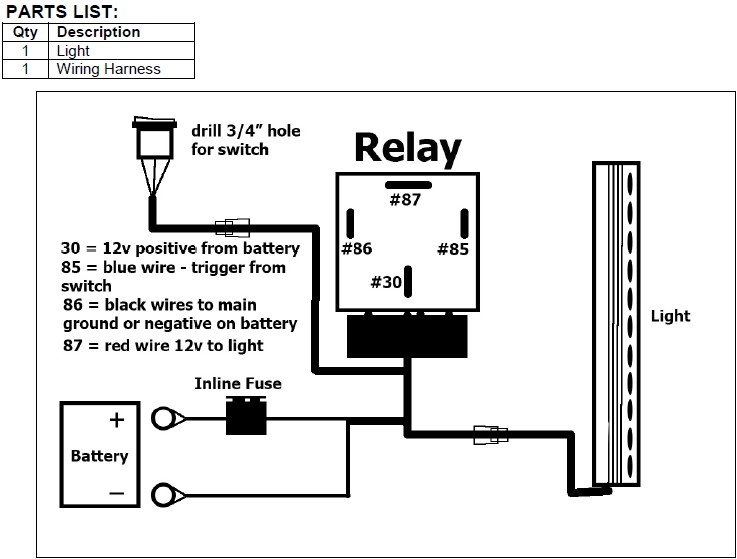

1. REMOVE CONTENTS FROM BOX. VERIFY ALL PARTS ARE PRESENT. READ INSTRUCTIONS CAREFULLY. DRILLING IS REQUIRED. ELECTRICAL KNOWLEDGE IS HIGHLY RECOMMENDED.

2. Install Light into product as instructed. Open hood and disconnect battery.

3. Unwrap preassembled wiring harness. Disconnect the plug in the harness leading to the lighted switch. Locate suitable mounting location for switch. Drill 3/4” hole in panel to mount switch. IMPORTANT: Do not drill any holes in panel until back of location is properly checked for clearance. Use of safety goggles is required.

4. Run switch harness through firewall on vehicle. Drill hole through firewall as required for harness plug. Highly recommend use of rubber grommet (not included) to protect harness. Feed switch harness plug through hole in firewall. Seal firewall with silicone as necessary.

5. Attach Relay and main harness to suitable location near battery (firewall or inner fender for example). Do not connect to battery at this time.

6. Attach switch plug to switch harness and tie harness away from anything that could damage harness.

7. Run the prewired light harness down to the light. Plug harness into prewired plug on light. Tie wiring harness away from anything that could damage harness.

8. Attach the fused red positive and black negative wires on the main harness to the battery. NOTE: Attach black negative wire to negative terminal on battery or suitable chassis ground.

9. Reattach battery cables to battery. Installation is complete.

10. Do periodic inspections to the installation to make sure that all hardware is secure and tight and all wiring harnesses are properly secured and free from excessive movement.