When looking at the differences between a two door Wrangler and a four door, wheelbase/length is certainly the most noticeable thing. This plays an important role when discussing suspension lifts and their impact on drive shafts. In this tech guide we’ll discuss the effect lifting a Jeep has on the drive shaft and differences between a two and four door Wrangler.

Contents

- How a Driveshaft Functions

- When to Upgrade a Wrangler's Driveshaft

- The Significance of an Aftermarket Driveshaft with Suspension Lifts

- Wrangler CV Driveshafts, Off-Roading, and Grease

- So What's the Difference Between Two-Door & Four-Door JKs?

- Can Modifying My Suspension Help My Driveshaft?

- What Size Lift Can I Safely Run on My JK? Two-Door & Four-Door

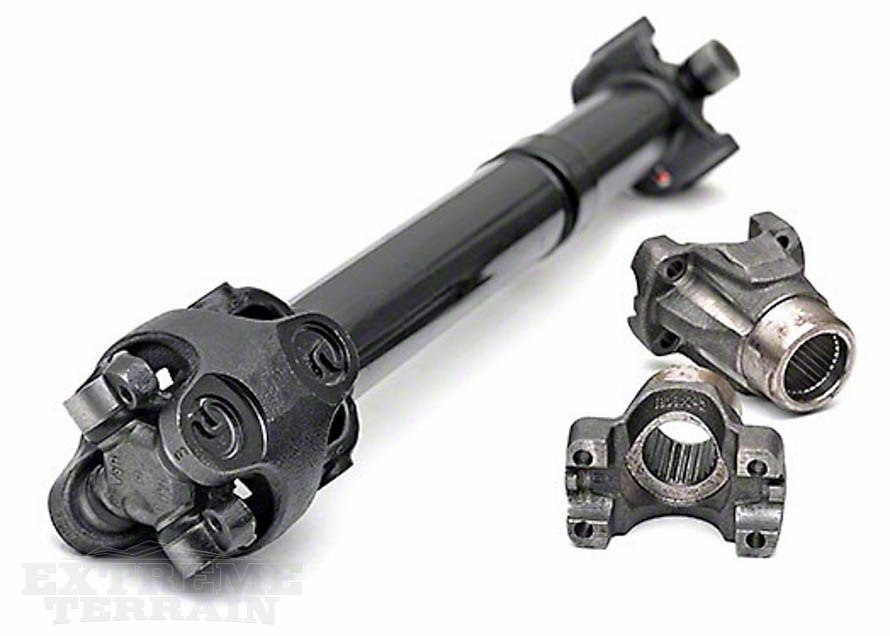

Shop Wrangler Driveshafts

Your Wrangler's driveshaft keeps your tires rolling, and the power moving. Snapping a driveshaft while on the trail is the worst; no way to even limp your rig home! If you're an off-roader, an aftermarket driveshaft will serve you well.